Waterproofing of flat roofs: installation and heating. Virvi waterproof plastic HL Virvi waterproof for used roofing

HL roofing drains with vertical outlet - HL 62, HL 62.1 and others, are suitable for various types of flat roofs, both for non-use and for use. The HL roofing systems are combined with different structures (types) of the coating and the surfaces of the “pie” of the coating. Mounted on existing roofings, insulated flat traditional roofings, roofings made from corrugated sheets (profiled sheets), “green roofings”, and can be installed on balconies and terraces. Virvi HL is designated for the removal of roof water and melt water from roof drains.

In whose section it is indicated:

Virvi HL with a vertical outlet for unused roofs. From the leaf catcher. DN - 75, 110, 125 or 160;

Virvi HL with a vertical outlet for roofs that are in use. With brackets (150x150 mm) made of stainless steel. DN - 75, 110, 125 or 160;

Virvi HL with a vertical outlet for roofing with corrugated sheets. DN - 75, 110, 125. For installation in roofs with insulation thickness - 100-160 mm.

Additional equipment for HL roofing systems - extension elements, cushions, waterproofing flanges, various sheet metal catchers, anti-fired couplings.

Virvi HL with a vertical outlet for unused roofs. From the leaf catcher. Rozmiri – DN 75, 110, 125 or 160.

|

Description |

|||

|

The roof is made of sheet metal, with thermal insulation, with an extrusion flange made of stainless steel (with union nuts/wings), with a vertical outlet. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|||

|

Like the roof of the HL 62, and with electric heat. Self-regulating heating cable. Tension – 10-30 W. Voltage – 230 W. |

|||

|

HL 62 P |

|

Cover with sheet metal, with a body made of PVC (polyvinyl chloride) with thermal insulation for gluing the PVC membrane, with a vertical outlet. Recommended for PVC membranes. |

|

|

Like a cover with HL 62P, and with electric heater. Self-regulating electrical heating cable with tension 10-30 W, 230 V. |

|||

|

HL 62 F |

|

The cover is made of sheet metal, with a body made of PP and thermal insulation for gluing waterproofing FPO membranes. With vertical outlet. Recommended for FPO membranes (PP based). |

|

|

HL 62.1 F |

|

As a cover HL 62F, and with electric heater. Self-regulating electrical heating cable with tension 10-30 W, 230 V. |

|

|

The cover is made of sheet metal, with a body made of PP with thermal insulation, with a waterproofing polymer-bitumen sheet with a thickness of 2.5 mm and a diameter of 500 mm. Recommended for waterproofing materials that are fused to a bitumen base. With vertical outlet. |

||

|

As a cover HL 62H, and with electric heater. Self-regulating heating cable. Tension – 10-30 W. Voltage – 230 W. |

|||

|

"Universal" types for unused roofs with sheet metal. With universal fittings for steel, steel and plastic pipes. |

|||

|

“Universal” roofing system, with sheet metal, with an extrusion flange made of stainless steel (with union nuts/wings), with flexible rings, with a vertical outlet. This liner easily and reliably connects to pipes made of any material (steel, steel, plastic). The valve is inserted into the middle of the pipe and does not interfere with the compensation pipes. |

|||

|

HL 69 P |

|

“Universal” roofing pipe, with a sheet metal hose, like HL 69, and with a PVC flange, for fastening a PVC membrane, a pipe with flexible rings, with a vertical outlet. The HL 69P funnel easily and reliably connects to pipes made of any material (steel, steel, plastic). It is inserted into the middle of the pipe and pulls out the compensation pipes. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|

|

HL 69 H |

|

“Universal” roofing material, with sheet metal like HL 69, and with polymer-bitumen fabric, with flexible rings. With vertical outlet. Virva connects to pipes made of any material (steel, steel, plastic). The valve is inserted into the middle of the pipe and does not interfere with the compensation pipes. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|

Virvi HL with a vertical outlet for roofs that are in use. With frames 150x150 mm made of stainless steel. Rozmiri – DN 75, 110, 125 or 160.

|

Description |

|||

|

HL 62 B |

|

A roofing system with thermal insulation, with a pressure flange made of stainless steel (with union nuts/wings). With a vertical outlet. Recommended for waterproofing polymer membranes: EPDM, EPB, ECB (ethylene polymer-b itum), EVA (ethylene vinyl acetate), PIB (polyisobutylene) etc. |

|

|

Like a roof HL 62B, and with electric heater. Self-regulating electrical heating cable with tension 10-30 W, 230 V. |

|||

|

HL 62 VR |

|

Covering system with thermal insulation, with a body made of PVC (polyvinyl chloride), for gluing PVC membranes, with a vertical outlet. Recommended for used roofing with waterproofing from PVC membranes. |

|

|

HL 62.1 BP |

|

Like a cover with HL 62BP, and with electric heater. Self-regulating electrical heating cable with tension 10-30 W, 230 V. |

|

|

HL 62 BF |

|

Coating with thermal insulation, with a body made of PP (polypropylene) for gluing FPO fabric. With vertical outlet. Recommended for coating with waterproofing FPO membranes (PP based). |

|

|

HL 62.1 BF |

|

Like a roof HL 62BF, and with electric heater. An electrical cable that self-regulates and heats up. Tension – 10-30 W. Voltage – 230 W. |

|

|

HL 62 BH |

|

The roof is made with thermal insulation, with a waterproofing polymer-bitumen sheet with a thickness of 2.5 mm and a diameter of 500 mm. With vertical outlet. Recommended for waterproofing materials that are fused to a bitumen base. |

|

|

HL 62.1 BH |

|

Like a roof HL 62 BH, and with electric heater. An electrical cable that self-regulates and heats up. Tension – 10-30 W. Voltage – 230 W. |

|

|

"Universal" tools for operating roofs with gratings (150x150 mm) made of stainless steel. from universal fittings to steel, steel and plastic pipes. |

|||

|

HL 69 V |

|

“Universal” roofing system, with sheet metal, with an extrusion flange made of stainless steel (with union nuts/wings), with flexible rings, with a vertical outlet. Virva simply and reliably connects to pipes made of any material (steel, steel, plastic). The valve is inserted into the middle of the pipe and does not interfere with the compensation pipes. |

|

|

HL 69 VR |

|

“Universal” roofing pipe, with sheet metal, like HL 69 B, and with a PVC flange, for fastening the PVC membrane, with flexible rings, with a vertical outlet. Virva HL 69 BP connects to pipes made of any material (steel, steel, plastic). It is inserted into the middle of the pipe and pulls out the compensation pipes. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|

|

HL 69 BH |

|

“Universal” roofing material, with sheet-metal material like HL 69 V, and with hydroisolating polymer-bitumen fabric, with flexible rings. With vertical outlet. Virva connects to pipes made of any material (steel, steel, plastic). The valve is inserted into the middle of the pipe and does not interfere with the compensation pipes. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|

Viruses with a vertical outlet for roofing made from corrugated sheets. DN - 75, 110, 125. For installation in roofs with insulation thickness - 100-160 mm.

|

Description |

|||

|

Virva Kolyvelna for the Pokrivel with a corrugated board, with a leaflet, we wrap it with a flange with stainless steel (with clocking nuts/"lambs"), with a heat -zo -vel, with an outbreak of a box (regulovnia in the ears - 100-160 mm). With vertical outlet. Recommended for hydroisolating polymer membranes: EPDM, EPB, ECB (ethylene-copolymer-bitumen), EVA (ethylene-vinyl acetate), PIB (polyisobutylene) etc. |

|||

|

Like the roof of the HL 63, and with electric heat. An electrical cable that self-regulates and heats up. Tension – 10-30 W. Voltage – 230 W. |

|||

|

HL 63 P |

|

Virvel is Virva for the Pokrivel with a corrugated board, with a leaflet, with a heat, with a rosema, with an editing box (a thoroughly-100-160 mm regulovnim), the HL 63, Ale with a smooth flange of the PVC, for the PVC-membranes KRIPLENNE. With vertical outlet. Recommended for PVC membranes, lightweight roofs made from corrugated sheets, with insulation thickness - 100-160 m. |

|

|

HL 63.1P |

|

Like a cover with HL 63 P, and with electric heat. An electrical cable that self-regulates and heats up. Tension – 10-30 W. Voltage – 230 W. |

|

|

HL 63 H |

|

Coating system for roofing with corrugated sheets, with sheet metal, with thermal insulation, with a separate mounting box (adjustable in height - 100-160 mm) like HL 63, and with a waterproofing polymer-bitumen sheet. With vertical outlet. Recommended for waterproofing materials that are fused to a bitumen base, lightweight roofing with corrugated sheets, with insulation thickness - 100-160 m. |

|

|

HL 63.1H |

|

Like a roof HL 63 H, and with electric heat. An electrical cable that self-regulates and heats up. Tension – 10-30 W. Voltage – 230 W. |

Additional equipment for coating sprayers with vertical outlet of the HL 62 series

|

Description |

|||

|

Extensions for shower chairs series HL 62 |

|||

|

An extension element with a pressure flange made of stainless steel and a humic gorge ring, 345 mm high, is sealed for a hermetically sealed connection with waterproofing, as well as with a roofing line on flat surfaces. insulated roofs where vapor barrier is evident, DN 125 |

|||

|

The extension element with a hydroisolating polymer-bitumen fabric and a gum ring of a gullet, 345 mm high, is sealed for a hermetically sealed connection with the bitumen-based waterproofing, as well as with a roofing strip on flat insulated roofs when vapor barrier is evident, DN 125. |

|||

|

HL 65P |

|

The extension element made of polyvinyl chloride, with a humic ring of the gullet, with a height of 345 mm, is sealed for a hermetically sealed connection with waterproofing from PVC membranes, as well as with a roofing compound on flat insulated roofs where vapor barrier is evident, DN 125. |

|

|

HL 65F |

|

Extension element made of polypropylene, with a gum ring of the gullet, 345 mm high, sealed for a hermetically sealed connection with waterproofing from the FPO canvas, as well as with the coating layer on flat surfaces on filmy roofs where vapor barrier is evident, DN 125. |

|

|

HL 65PE |

|

Extension element made of polyethylene (PE), for gluing FPO membranes (PE based). |

|

|

HL 350.0 |

|

An extension element with a profiled flange is assembled for mechanical fastening (underlaying) of another level of waterproofing. Height – 220 mm. DN 145 |

|

|

HL 350.1 |

|

An extension element with a pressure flange made of stainless steel, with a drainage ring made of PP for receiving water flow and an installation kit, can be installed for bitumen waterproofing. Height – 220 mm. DN 145 |

|

|

HL 350.1H |

|

Extension element with waterproofing polymer-bitumen fabric, stacked to fit another level of waterproofing, height 225mm, DN 145 |

|

|

Shoes for shoes HL 62 series |

|||

|

Liner for paint covers and extension element HL350.0, height 155mm. DN 145 |

|||

|

HL 350.2 |

|

HL 350.1 with additional inputs. DN 40 |

|

|

Waterproofing flanges for washbasins HL 62 series |

|||

|

HL 84 |

|

Waterproofing flange with EPDM membrane 500x500 mm for roof drains. |

|

|

HL 84.0 |

|

Waterproofing pressure flange made of stainless steel with a diameter of 220 mm for roofing pipes. |

|

|

HL 84.CU |

|

Waterproofing flange with a copper sheet 500x500 mm, for coating paints. |

|

|

HL 84.E |

Waterproofing flange with galvanized steel sheet 500x500 mm for roof drains. |

||

|

Sheet catchers for casters HL 62 series |

|||

|

HL 160 |

|

Drainage flange for receiving water flow from waterproofing on inverted roofing. Ø 170 mm. |

|

|

HL 161 |

|

Drain flange HL 160 comes complete with adapter Ø145 mm to Ø125 mm. |

|

|

HL 170 |

|

Flat sheet metal catcher for roofing tools of the HL 62 and HL 64 series. Ø 170 mm. |

|

|

HL 175 |

Stainless steel sheet metal catcher for roofing jets of the HL 62 and HL 64 series. Ø 145 mm. |

||

|

Counter couplings for HL 62 series |

|||

|

HL 850 |

|

The opposite coupling for the HL 62 series (DN 75), between the inserts EI 120, which consists of a metal body with expansion material and a yoke, with a mounting plug. Vikorist is especially suitable for DN 75 outlets. |

|

|

HL 870 |

|

The opposite coupling for roofing screws of the HL 62 series (DN 110), between the inserts EI 45, which consists of a metal body with a material that expands, and a yoke, with a mounting plug. Vikorist is especially suitable for outlets DN 110. |

|

Purpose:

The roofing hose is designed to remove water from the roof and melt water from flat roofs to the roof drainage system.

Description:

Coating spray for used roofing with a horizontal outlet DN 75, DN 110, with a decorative extension with PP grommets to prevent nails and leaves from entering the drainage system, with a clamping element made of stainless steel This steel, with electrical heating from 220V to 120V. A self-regulating cable for electrical heating is laid in the middle of the virtu body. The long end of the power cable will be pulled up and down.

Equipment:

1. Eccentric transition from PP DN 75/DN110

2. Profiled sealing element made of stainless steel for sealing waterproofing (vapor barrier).

3. Set for fastening the clamping element: ram and washer made of stainless steel (6 pcs each)

4. Support flange for extension element.

5. Extension element with PP with stainless steel mounts 150x150 mm.

6. Funnel body made of PP and secured with steel landing pins (6 pcs.)

Today's flat-covered buildings, which are ideal for virobichnykh and richly surface dwellings, are becoming more and more common in private households. Such a design allows you to remove additional areas for finishing a terrace, a sports square, a swimming pool, or a garden. To ensure the protection of the roofing coating from damage caused by water inflow, it is important to install an effective system for draining melt and rainwater, and ensure proper installation and heating of water intake funnels.

Select water drainage system

For flat type dakhs there are two options for drainage systems:

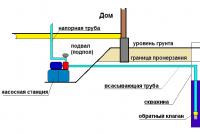

- Traditional (involves installations of a large number of virvs, water through the pipes of the system is self-propelled).

- Gravity-vacuum (increases high throughput with minimal communication).

Traditional internal drainage. For effective operation, it is necessary to correctly mount the roof lining, in which the worms are mounted at the lowest points. A lot of water should be stored depending on the size of the hole. The water receiving elements through the help of pipes are connected to a vertical drain pipe, through which the water flows from the mouth into the sewer. It is important to install horizontal elements of the pipeline behind the joint to ensure that self-fueling water can easily drain out.

Gravity-vacuum system. More than 30 countries are actively stagnating in rich countries of Europe and the world due to their high economics and efficiency. The principle of operation is based on the fact that in a system equipped with a siphon, it is based on the vacuum center, through which the water rises from the surface and moves through pipes with high fluidity. The system can be upgraded:

- The flow has high fluidity;

- simplified installation (fewer funnels and communications are required, pipes do not need to be installed under the pipe, as the water moves through them under the pressure of the wind);

- the water is low (does not create additional leakage on the roofing system);

- cost-effectiveness (funnels and pipes of smaller diameter can be installed in line with the traditional system without loss of productivity);

- The capacity is self-cleaning (the throughput capacity of the system does not change over time).

For leveling: a vacuum system with a horizontal outlet of 75 mm can release up to 15 liters of liquid per second. To ensure the same throughput of a traditional drain, it is necessary to install a drain with a horizontal outlet of 200 mm.

During severe storms, a large volume of water can accumulate on a flat surface, which the drainage system cannot cope with. In order to avoid collapse of the structure through the surface area, it is necessary to install a special additional drain - a drain. You can also cancel the function of the main drain while cleaning the rest.

Select water spout

Wires for lining internal drains are made from polymers, metal or combinations of materials. When choosing a flooring, it is important to choose the type of material that you choose. The metal wires are assembled for installation on buildings covered with sheet metal. Polymer windows are suitable for installation on soft roofing.

Virva for a flat dahu can be either round or rectangular in shape, horizontal or vertical. The choice should be based on the location of installation and the particularities of the coating. The wires are separated behind the structure, but in any case it is possible to firmly attach the wire to the base and ensure reliable waterproofing of the fastening unit.

Wires with a metal flange are fixed using a pressing method using additional fastening elements made of stainless steel. The wires have a polymer flange, secured with a reinforced cuff, and are fastened with adhesive.

The water drainage system must be protected from contamination. To avoid getting caught in the drains of the great smitten, you should protect yourself with dry crusts and screens. Vibrobis with flat tops and slits are used on covers that are in use. The kryshki of the building vitrimuvati vaga people. If you want to create a “green” cover, it is better to use funnels with a leaf filter to look like a mesh bag.

The principle of placement of water intakes

Water traps must be installed at the lowest places on the roof. It is responsible for even distribution on the surface. In order to prevent the formation of stagnant stains on the surface, the surface impurity at the bottom of the drain should be no less than 2%, while at a distance of about half a meter to the drainage drain, the drainage should increase to no less than 5%. Replacing the repair will be provided for the repair of the screed or the replacement of the heat-insulating ball.

The size of the amount of water taken is as follows: the area of the skin area should be no more than 200 square meters. m. surface, the distance between the showers is no less than 50 cm. The minimum diameter of the pipe is 10 cm. Regardless of the size of the pipe, at least two showers can be installed on it, or one shower and a drain. This is to allow the flooding to subside during the time when the water intake is washed out.

By adjusting the number of water inputs and their parameters, the intensity and frequency of rainfall in a given region is controlled.

Installation of internal water drainage system: installation of funnels

First option. The most practical in operation are storage bins, the body of which is folded into two parts. For the lack of dynamic reserves, such virvy, in addition to rigid structures, compensate for the collapse of the insulation system.

The water intake device begins with the installation of the lower part of the storage line in preparation for the passage opening, making sure that the air is blocked. The lower part is inserted at the groove, and the fastening does not have to be rigid in order to avoid damage to communication due to temperature deformations.

The outer part of the rope for creating an internal drain is installed on the surface, passing through the roofing rim and a ball of insulation, and it is inserted into the lower part. Between the parts of the virus of transmission there is a ring gorge. The plastic apron of the upper part must be laid on the lower ball of the roofing felt lining. An additional ball of lining is mounted on top of this and a bitumen apron is fused into the core of the ball of waterproofing. An outer ball of covering material is mounted on top of the apron, which is inserted into the bowl and secured with a pressure ring and stainless steel fasteners. At the last stage of installation, dry grates are installed on the surface.

Another option. The water intake device with the pressure flange involves a number of stages. It is recommended to fasten the wire not to the insulation material, but to wooden blocks corresponding to the cut, securely fastened to the base of the roofing. The wire is firmly inserted into the hole (it is firmly secured), between the flat side of the wire and the pressure flange a humobitumen gasket is installed, which is laid under the roofing keel. At the initial stage of installation, the metal pressing flange is fixed with special stainless steel fasteners. To install the fastening elements at the flange, the chute gasket and the side of the transfer funnel, open it. Once the installation is complete, the cover is secured.

The principle of water inlet funnels depends on the configuration of the system and the type of roofing coating. When installing the track, follow the manufacturer's recommendations.

Heating of drinking water

Drainage funnels in cold winter climates will require heating to prevent ice plugs from forming in the pipe and adjacent sections of the horizontal pipeline. The frost depth reaches one and a half meters, so it is recommended to transfer heating and these elements of the drainage system.

The freezing of water in the pipes and pipes leads to flooding of the surface during the period of snowfall, and the debris from the snowy changes of ice in the melted thermal insulator (the insulation ball in the roofing pyrite) is dissipated in the remaining black gu.

Currently on sale are machines for flat roofing, already equipped with a heating system. But the powerful forces of the stench will cause problems: the cork stopper will start to grow. Of course, you won’t need to remove the internal water, otherwise you can create a serious problem by blocking the flow of water to the drain.

To ensure that the water supply system functions properly throughout the entire period, install a self-regulating heating cable for the roof around the maidanchik heating system. Which type turns off the possibility of clogging the drain with ice

Warning: Use of undefined constant callback_thumbing_img - assumed "callback_thumbing_img" /var/www/krovgid/data/www/site/wp-content/themes/krovgid/kama_thumbnail.php on line 337

Without proper organization of the drainage system, the flat boat will likely require scheduled repairs. Stagnant board and melt water on the surface is gradually crushed into a dry ball of crust. As a result, the basis is exposed to rapidly collapse in the face of inveterately attacking sleepy changes. When water crystals freeze, it is easy to tear the material.

You can prevent and avoid negative inflows by properly installing a drain on a flat roof. The rules and principles of governing such an important water supply system must be carefully read by the rulers, which ensures the effective and long-term service of the deputy government.

The development of a flat roof drainage system requires a comprehensive organization of drainage of rainwater and melt water from a sensitive surface. This can be done effectively throughout the whole river without removing powdery clogs, crusty and leafy plugs.

Regardless of the readings of thermometers and precipitation, the drain must accept and promptly transfer the rare substance to the sewer, to a container for collecting rain water, or simply to the ground.

Classification of litter removal systems

To ensure that water is transported without changing the code or changing the code, you need to know exactly what type of system to choose to handle the moisture content:

- Foreign non-organizations. What does a fleeting glass of atmospheric water convey? To glaze small gospodar's budіvels, put together a few curls on more than two surfaces.

- External organizations. The collection of water is transferred through additional gutters or gutters together with the watering cans with further transmission to the drainage pipe. The system is laid along the eaves and outside sides of load-bearing walls. Vikorist is used in equipped residential and non-residential buildings, especially low-surface ones, but the scheme is permissible for organizing the flow of water from buildings with a height of up to five surfaces.

- Internal. It is clear that the water intake is carried out by means of drainage funnels built into the roofing system specifically for flat roofing. The water is discharged through risers located in the middle of the water that is being formed.

Modern drainage systems operate efficiently in cold regions, where water in pipes rarely freezes or does not freeze during any cold period. For areas with a humid climate and smoky climate, external drains are recommended, including for roof structures.

On the roads without a mountain, we can practically melt snow without interruption all winter, because the shutdown is gradually warmed up by the heat that comes in the middle. Sinking into the cold pipelines, the melted water formed into a congee.

If the mountain is flat, the snowmaking process can be regulated. By opening the auditory windows, the temperature on the roof can be reduced significantly, so that the snow melts more or stops altogether.

In the lower regions there is a threat of the roof rupturing during a sharp cold snap. A plug may form in the pipes, blocking the flow of water that is lost in the water. When the substance crystallizes, it becomes noticeably more active, which causes damage to the coating that has absorbed it. Therefore, in the ancient and dead latitudes, it is necessary to equip the non-living ones with external drains. non-heating will be and will be at the designed low temperature.

Cold storage containers, for example, have a wine tray with a side and a drain riser. A large area of such spores accommodates equal temperatures of the system and an excessive amount of fluid, which is why the leaky plugs are not cleared.

Residential buildings with flat gutters, built in areas of the dark and dead smog, are lined with internal drains. Spores are more expensive, but it’s safe for the whole river. The risers, which are placed in the middle of the building, are gradually heated by internal heat, which overcomes the presence of ice blockages in the pipelines. At modern latitudes, drainages of the new variety are dominant.

Structural components of gutters

The installation of external and internal drainage systems is rich in strength. The skin system, which is used for flat teeth, includes elements similar to those of design, such as:

- Water intake drains and gutters designated for receiving wastewater and transferring it to the trench.

- Risers What to ensure at the points where the maximum fluidity of the stream of water is received against the forces of gravity.

- Drainage pipelines, which are necessary for the removal of atmospheric fallout to the objects of destruction.

The main guideline for designing a drainage system is the minimum drainage of the main line from the point of water intake to the point of drainage of the system. The shortest and cheapest modern option involves a riser with a pouring or groove at the top and a short outlet at the base.

The outlet should be installed under a small hole at a distance of 20 - 45 cm from the surface above the drainage sewer or simply above it, protected from the erosion of the pavements. However, equipping the cabins with a drainage system of this type is most often required by non-overflowing conditions: the absence of a drainage system, weak soils, an old foundation, the presence of water is not necessary.

Since it is impossible to lay a small main, other routes for draining water are being explored: from the riser, a ground or underground pipeline is installed, leading to a handy place for drainage.

The scheme with the pipeline is completely incompatible with the structure of flat roofs with an internal drain, and even the system is responsible for transporting water between the walls.

Specificity of molding uhilu

To stimulate the independent flow of water directly, it is necessary to form a mixture of 1-2% on flat surfaces:

- To organize a new type of drainage, the entire area is covered up to the area where the gutter is installed. Most often this is the back wall.

- To organize a stream of water behind the internal circuit, a hole is created until the water is installed. The vein is formed using the envelope principle so that near the skin water-receiving point there is a reduced radius of 50 cm.

Water intake funnels of internal drainage systems can be installed not only in the central zone of the building, but also on the outside wall at a distance of at least 60 cm from it. Therefore, the envelope circuit design has a lot of different options.

In any case, the surface area may be straightened at the side of the water intake. And since there are a number of watering cans installed on the boat, between them there is a kind of “water pipe” - a miniature like a mountain ridge, designed to direct a stream of water directly to the nearest watering can.

For the best possible shaping of the joints there are a number of practical methods:

- Vlastuvannya nakhil in the process of waiting for the additional installation of a block under the required cut.

- Backfilling of expanded clay in the shape of a wedge-shaped ball with the subsequent pouring of a cement-pastic screed.

- Organization of the installation of wedge-shaped slabs of mineral wool insulation.

The construction of large-sized surfaces requires the help of special ones that form the metal structure. It’s rare to stagnate in private life.

Rules for internal drainage

To suit any object that is under construction, the drainage system of a private cabin must be insured and designed in advance. It is necessary to select the shortest possible route for laying the pipeline and transfer it to the most convenient place for connecting it to the sewage system.

The organization of internal drains comes in a variety of ways. They must be used in areas with and without mountains, in exploited and unexploited categories. According to the planned specifications of the booth, the independent designer should ensure that:

- Drainage risers are usually installed in the area of drainage cells, walls, columns, and partitions. Placed near living quarters for instant heating during cold periods. The monolithic risers near the wall are strictly protected. Can be installed in grooves, shafts, boxes. It is recommended to obtain them from comoras or similar auxiliary products.

- When organizing a non-fired drainage system, it is necessary to develop methods for individual heating of funnels and risers. To increase the temperature of the external elements of the flat stove, install an electric cable that heats, or install risers using steam scorching.

- The flat valley behind the mountain is best equipped with a pipeline that will pass between the mountain expanse. It is framed as a hanging frame. To ensure drainage, horizontal pipe sections of the suspension system are installed with a slope of 0.005. Tobto. per linear meter of pipe there may be a 5mm reduction at the water outlet.

- Before the installation of overhead pipelines, the drainage area in the burn zone needs to be insulated.

- Since it is impossible to install a suspension system, it is impossible to install the pipeline underground. There are no regulations to protect the depths of the underground. Make sure there is a connection to the sewage system. However, the underground circuit is significantly more expensive, and is inherently difficult to control and implement repair work. In addition, their implementation may overwhelm the overly-tight foundation.

- When designing a scale, you can trace the uniqueness of the logins.

- The riser at a distance of about a meter above the surface of the ground must be inspected for cleaning.

In fact, the drainage from a flat roof can be organized like a standard drainage system: with inspection wells, inspections, etc. The suspended drainage pipeline has ceramic, plastic, chavun, and asbestos-cement pipes that are exposed to pressure when washed.

For laying underground parts of pipes from these same materials, but without the need for hydrostatic conditions. Durable rolled steel pipes tend to stagnate at industrial sites due to characteristic manifestations of vibration.

In accordance with technological requirements, one water collection funnel can receive atmospheric waste from a drain with an area of up to 1200 m², and the distance between the water intakes is not less than 60 m. Wait, the designated scale for low-surface everyday life is not necessary for the authorities. In short, in a small private booth, I would like to have one virva.

It is necessary to increase the number of water receiving devices if:

- The coating area exceeds the boundaries specified by GOST.

- Booth of divisions in the section. Then equip the skin with a damp cloth.

- Between one roofing structure there are separation elements by parapets, temperature or expansion joints. The skin sector of such a dahu is guilty of two water intakes.

Water collectors are produced for operating and non-operating flat pipes, for containing structures and systems with open spaces. Є models that are installed in laminated concrete slabs with bitumen coatings and wooden analogues coated with . For all options that are used in everyday life, water supplies are prepared from chavun, ceramics, galvanized steel, and polymers.

Water receiving devices are available in a variety of sizes. The standard design consists of a center-facing shower with wide sides and a removable cover with openings to ensure a stream of water.

More collapsible representatives of the class of coating machines are additionally equipped with a parasol, which protects the drain from contamination, a special bottle and a pressure ring, intended for pressing the edges of the soft coating on the device. All models are subject to maintenance and cleaning.

Regardless of the model, all water receivers are presented with equal benefits:

- The bowls of the water collectors are firmly attached to the covering or load-bearing flooring. For fixation, at least two clamps are used.

- After installation, you must ensure the tightness of the coating on the installation site.

- The pipes are connected to the risers using additional expansion joints, which help to maintain the tightness of the connection during shrinkage of the building structures.

- The suspended systems are equipped with shaped leads.

- The water inlet bowl is installed below the level of the finishing coating to prevent stagnation of water. Water tanks on doors that are not in use tend to have a round shape, causing stench to hang over the surfaces. Cups of funnels for stoves that are in use are installed level with the tiles, in terms of being square, so that it is easier to lay the tiles next to the structure.

To improve sealing and reliability in the area of the crossbar of the lightweight roofing structure, partial thermal insulation is allowed. Primary type coating systems are equipped with single-level laths.

And those that rely on mechanical fastening have domestic water inlets that ensure the collection of water over the waterproofing and vapor barrier.

Roof structures with polymer membrane coatings are usually coated with water inlets with a pressurized polymer flange, which is glued or welded to the coating.

The development of new types of gutters made from flat roofing is carried out in the same regions. Their devices in residential and office buildings are recommended in areas with insignificant fallout, which usually does not exceed 300 mm per river.

The class of external water supply systems for rainwater and melt water includes:

- Unorganized drains, recommended for drainage in dry areas. Preferably, before the designated scheme, water is supplied by self-fuel along the eaves.

- Organizations of drainage, recommendations for the management of non-living budinkas in snowy and tame latitudes, living budinkas in sunny regions with insignificant indicators of rainfall. The principle of operation lies in the systematic collection of waste from the external drainage basin with adjacent straight sides or into gutters with further drainage from the drainage system or into the ground.

Until now, the solution to the system of the modern type has been created by many talented people. The idea lies in the inclusion of a food filter at the water supply to purify the rain water, which is installed after the water intake.

To improve the drainage and the reception of purified water, install a container. Well, of course, the connection between the system and the sewerage system is affected. This scheme allows you to clearly solve two problems: to remove water from the drinking water and to protect the water from stagnant water.

An unorganized type of drainage system will require strengthening of the eaves. They need to be covered with galvanized roofing steel, and then the animal should be covered with balls of rolled roofing. The additional balls are laid with an overlap.

The increased susceptibility of the mastic flat covering follows the analogy. Instead of balls that are glued, apply mastic balls to bitumen or bitumen-polymer material, sealing them with reinforcing shells of creased fabric or geotextiles. The main reinforcement ball behind the reinforcement is responsible for bending the edge of the metal upholstery of the cornice.

Fixing the external drain on the eaves of a flat roof follows the traditional scheme. We sell a number of ready-made kits with briefing instructions for assembling systems. Brackets are attached to the front plate to simply install a gutter made of plastic or metal modules.

For further transportation of water, a water inlet spout with a pipe is installed to which the riser is connected. The pipe is fixed to the wall using additional brackets. The edges of the system are closed with plugs and completed with the installation of a shaped outlet.

Video instructions for installing gutters

For details on the principles of internal drainage systems and the specifics of their installation on a flat roof, watch the video.

Folding and installation of the external drainage system:

Vlashtuvannya khilіv on a flat dakha:

Installation of a water intake line for the internal drain

Information about the guidelines for choosing the optimal drainage system will help you properly treat your water with a reliable protection against runny water.

Knowing the technological principles will be useful to the independent masters and rulers of the castle's inviolability, who are likely to turn into the servants of third-party Viconavians. Properly repairing the drain will help protect the bathroom and the destruction of household materials, will serve you for a long time, without causing problems.

The main enemy of any kind is water, a ruinous action that leads to shortening the service life of the coating material, leakage. In two-spirited, hip and one-spirited species, there is a need to drain melt and board water.

These are the slopes, the veils of the vologa, without bothering with the breath, they climb down. Flat coatings are less susceptible to damage, and caulk accumulates on a flat surface, which cannot be dried out.

Stagnant water methodically collapses the waterproofing ball, in addition to which the water, which is applied by the wind, settles in them, hardening the swampy substrate. All the plants that have sunk into this “soil” are sprouting and leaving a covering pie for the roots. To ensure a long service life, have a drainage system that drains water from its surface into the drainage system.

Flat drainage system

The drainage system of a flat roof is a set of elements that collects, transfers and removes water that has accumulated on the surface of the roof as a result of falling rain or snow. have the following types:

- Non-organizations. The problem lies in the fact that the water simply squeezes out of steep liquids. This method of independent drainage is used in private houses with pitched roofs, but is not suitable for disputes with flat houses.

- External. It is formed from fastenings on the drainage surface or on the surface of drainage pipes. Self-fueling for the rakhunok uhilu dahu water is seen from the skhiliv and is angry at the trench or angry. The external drainage is constructed to drain water from the flat roof of a small area, to protect the government's spores.

- Internal. Typical types of internal drainage are those that are laid in the middle of the roofing cake. The specifics of the flat coating are not broken down.

Internal drainage of flat roof

Place not the ring, but under the balls of waterproofing, heat insulator. It consists of:

- Water drainers that are installed on the surface of the floor, in low places, which are weakened when weakened. The function of the funnels is to collect and filter melt and rainwater that goes onto the roof.

- Horizontal drainage pipes, which are installed under a ball of waterproofing and insulation under a layer, which is used to cover a self-filling drain, or without a layer, such as a vacuum one.

- Vertical trenches, which collect the flow of water that comes from horizontal pipes and discharge at the sewerage system.

The method of transferring water from the drainage system is either self-priming or vacuum. The principle of operation of a vacuum drain is that the waste fills the pipes that create the water drain, when the water flows downwards, the wind rises uphill, creating the vacuum middle, and then it draws in water from the drain funnel, as bi smoktuchi її. In areas with clear water, roofers recommend installing a vacuum system that can easily cope with large volumes of water and also self-clean through the flow of water through the pipes.

A drainage funnel on a flat roof collects and collects water that accumulates on the surface. The won consists of:

- The lower part, which is mounted on the base of a flat roof.

- A gap that tightly connects the upper and lower parts of the drainage spout.

- The upper part is subject to general insulation and waterproofing.

- The dry grate, which is located above the surface of the drain, protects the drainage nozzle from the penetration of large quantities of liquid and the creation of blockages.

The tightness of the floors between the elements of the drainage system is a must for the effective operation of the drainage system. When quilting a flat back, after leakage was detected in 70% of cases, the problem lay in the penetration of water between the sticks of the shower parts.

Types of drainage funnels

The coating and drainage coating can be made from galvanized metal, copper or polyvinyl chloride. Samplers from galvanized vikorist often sell for others, but at reasonable prices. The copper worms have not gained popularity through their arrogance, so they are more likely to smell of roofing materials. Polyvinyl chloride tiles are ideally suited for installation on soft tiles, shingles, and ondulin.

Specialized stores stock the following types of drainage funnels:

When installing drainage systems, professional roofers adhere to the following principles:

- Place the forces in the places that are located below the main level of Dahu. The difference between the base and the base should be at least 2 degrees, and at a distance of 50 cm it will increase to 5 degrees. Treatment is specified when using insulation slabs, expanded clay or concrete.

- The drainage spouts are distributed evenly over the surface of the flat surface with a size of 1 piece per 25 meters of water.

- Regardless of flat roofing, the minimum number of drainage pipes is two. So, as soon as the drain is caught in a storm or during times of severe storms, a friend protects the funnel so that it comes out of order or cannot cope with the large volume of water.

- The minimum allowable distance between the spouts of the drain is 50 cm. And from the edge of the drain – 1 m.

The order of installation

Install drainage funnels on a flat roof in the following order:

The drainage system, including the funnels, must be periodically inspected and cleaned so that a leak that begins uncontrollably does not lead to a collapse. Properly organizing a drain will help to extend the life of the roof, and will become a source of water for irrigation, as it contributes to the conservation of natural resources.

Video instructions