Possession and inventory of the hot shop. Today's technologically advanced possession of a hot shop. Installation of equipment, dishes, equipment for the hot shop

At the hot shop, organize: a plot for preparing soups, which has cauldrons of different sizes; a plot for the preparation of other herbs, equipped with stoves, deep fryers, frying pans, lubricated surfaces, small-capacity cauldrons, steam-convection ovens, grills, steam tables for herbs and sauces, dispensing stands with a heating oven; The plot for preparing hot drinks is equipped with electric boilers and kettles.

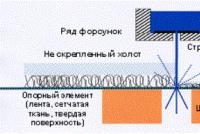

The installation of sectional modular equipment in hot and cold workshops represents an advance in the ability to organize work stations, since it is possible to assemble sequentially a number of work stations technological operations, such as washing and sorting cereals, shaking and washing greens, preserving products in the cold. This depends on the correct placement of equipment at work stations, interconnected with the technological process: thermal equipment, refrigeration cabinets, washing baths, testing tables, mechanical equipment, etc.

The main benefit to planning the work place is such a change in order to minimize the transition of the cook from one type of occupation to another. It is necessary to install sections-inserts with a water dispenser and inventory racks in order with the stoves, transfer the installation of tables and frying racks and frying pans, and place tables with equipped with bathtubs, and universal drives and cutting machines are owned by the same.

Of great importance is the order of placement of workers on production lines, as this determines the nature of transfer of service to service personnel. The shorter the route, the less time the energy of people will be wasted in the process of production, the more effective it will be for the victorious people to possess it. Properly organized technological lines make it possible to speed up the unproductive work of workers, ease the mind and experience increased productivity.

When placing equipment, it is necessary to adhere, first of all, to the principle of flow, so that during the final work of the cook there are no unproductive movements in the direct direction of the technological process.

During the cooking process, the cooks change their position as soon as possible and rotate no more than 90°.

For the rational organization of work places, it is necessary that the complete technological lines be maintained as a sequence of operations, and directly in which process is carried out. The productivity of cooks is 5 - 8% higher, since technological processes are straight from right to left.

It is obvious that all cooks are responsible for the protection of the robotic machines that are operated by a remote control, so it is important to open the doors of machines with mechanical drives (meat grinders, mince mixers, vegetable choppers, bread mills, etc.) Six heating units are right-handed, and the openings and trays are left-handed. . This also confirms that the processing process is caused by straightening the right hand to the left.

The remaining technological lines are separated by the overall dimensions of the workshops, and the linear-group method of placing equipment from technological processes is allowed. Parallel to the heat installation lines in the hot shop there are auxiliary installation lines.

Technological lines can be either side-by-side or side-by-side, or installed in one or two adjacent lines, parallel or perpendicular, before dispensing.

The hot shop is located on the same level as the halls. If there are many halls of the same designation, the workshop will be located on the opposite side of the hall with the largest number of spaces; On other surfaces, areas are transferred in which ready-made products are stored in the hot shop at food warmers, and a work area is organized for portioning and arranging herbs. The finished product is transported on top using coils. For the rest and placement on the tops of bays of various purposes, hot and cold workshops are designed for each of them.

The hot shop is subject to manual connections with the cold shop, food and kitchen utensils, places for slicing bread, shops - meat (meat-ribs) and sheep during the work of the enterprise in cheese and shops - cooking willows and loose greens, Since the industry operates on prepared products, with facilities for trapping and preserving cheese.

Due to the form of maintenance, the hot shop is responsible for the mother's hand connection with the placement of liquid distribution. At the hour of service by waiters, the shop comes right down to the serving area; for self-service establishments - to the bays, where distribution lines are located.

If restaurants serve both lunches and evenings, then the hot shop can operate at 1.5 change, or for food, then at 2 change.

At the hot shop, lines for the preparation of first and other herbs are organized from the workers who see the place for preparing: 1) broths; 2) fresh herbs; 3) hot drinks; 4) lubricating other herbs and side dishes; 5) boiling and stewing other herbs, sauces and side dishes; 6) baked herbs (Fig. 1). It is recommended that cooks’ work stations be equipped with modular sectional heat units (Table 5). Moreover, in small and medium-sized enterprises, thermal equipment is used periodically, in large enterprises – periodically and continuously.

The work station is also equipped with modular sections-tables: with a cold cup and hot pot for preserving herb components (SOECM-2 and COECM-3), with a built-in washing bath (SMVSM), for preserving spices, kitchen utensils, etc. ventilation, under mechanization (SMSM) .

The workshop is equipped with the following mechanical equipment: - Universal drive PU-0.6, which includes a meat grinder MC2-70 (it can be used for grinding boiled meat); sheep cutter MS10-160 for trimming raw vegetables; rich mechanisms MC4-7-8-20 for beating, straining, mixing products; Vegetable cutter MCI8-160 for shaped slicing of vegetables (in skippers, cubes, cubes, etc.); drive for hot shops PG-0.6, the warehouse includes: meat grinder MS2-70, dispensing mechanism MS12-40 for detailing crackers, zucchini, cavitation, etc., universal mechanism MS4-7-8-20, sievach MS24 -300.

When preserving products for a short time, refrigeration cabinets and racks are used. If pre-fabricated and ready-made products from culinary factories are delivered to food processing plants in functional containers measuring 530×325 mm (curls from 20 to 200 mm), then the products add heat Their samples, without taking into account them, are the internal dimensions of thermal energy, which are determined for of which, the external dimensions of the containers.

The containers are placed on refrigerated racks, transported to the appropriate heating units (stoves, frying pans, herbal cauldrons, greased ovens), and then the prepared urchin is served on the racks, refrigerated bain-marits, in heating ovens to the dispenser. This is a new operation of the technological process of preparing liquids with the provision of short-term routes for the transfer of finished products and finished liquids.

The most rational is the linear principle of placement of sectional modular equipment. Vikoristannya yogo allows:

it is rational to vikorystovat the virobnic area for the purpose of eliminating the gaps between different types of wall and island property;

promote productivity through rational organization of work places, elimination of wasteful transitions and unproductive waste;

speed up the number of internal shop transport operations; paint sanitary and hygienic washbasins by installing local ventilation units above the heat source, which capture vapors and decomposition products that are created during the thermal processing of products and are instantly safe feel the rush of clean air to the work area.

With the use of modular equipment, the work station of the cooks, equipped with two parallel lines (thermal and non-mechanical equipment), should be placed on a distance of 1.2-1.4 m, one side of the other.

A hot shop must be equipped with a variety of equipment: stock plates, chumichkas (for portioning herbs), skimmers (for removing pine), scoops (for pouring juice), strainers, etc. for cutting food - cook's three knives; carbuvaline (for figured cutting).

Characteristics of working places.

At the work station for preparing lubricated herbs and side dishes, install a deep fryer, a frying pan, a stove, and a refrigerated cooker, which saves fat in the prepared product. When deep-frying, place the products in a mesh insert and lower them into the fat heated in the deep fryer (there is 4-5 times more fat than the product). Using a strainer, remove the finished product from the fryer.

When frying foods, the main method is to heat the frying pan, add fat (bring it to a boil), and then add meat, fish, vegetables or other products. To turn them over, use vikory blades, and for stirring, use rainbows.

Grease a small amount of sprouts in a bowl on the stove.

If the vegetables are cut in a hot shop before being lubricated, then for this purpose a changeable mechanism for slicing vegetables is installed to a universal drive PG-0.6 or PU-0.6 for cutting a small amount of vikory board. with marked OS and knives of the cook's trio.

It's a hot shop. Where a large number of technological processes are involved, the necessary preparation of basic herbs may result in a number of variations in its structure, depending on the format of the enterprise itself.

Thus, having a hot shop in a restaurant is even more versatile and allows you to prepare a wide variety of herbs at once. Stravi is served in small (or single) quantities, depending on the skin client's needs. Just like the kitchen of a great community, it transmits uninterruptedly a variety of complex meals from many different varieties and great affairs, which, of course, creates a special specificity for its arrangement.

Zagalny characteristic

In the kitchen, preparation of broths, sauces, slicing and mixing of salads, temperature processing of prepared products, greasing and stewing of meat and vegetables are carried out. The inventory of a hot shop in a large warehouse is also responsible for ensuring the ability to bake bread, rolls and confectionery products, brew hot drinks and other gastronomic preparations. In addition, it is important to process the ingredients used for appetizers and desserts.

The same scheme will be used for the development of other ingredients, which must first be stored under the obligation of vibrating herbs. A building with several living rooms can include several kitchens, as well as one large one, placed on one floor with the hall, which allows for the greatest number of seating areas. In this case, a hot workshop is due to the mother’s free access to the warehouse, workshop, and, of course, ideally fit into the distribution system.

The kitchen equipment includes assembled equipment for thermal processing, as well as connections for electrical and mechanical appliances, electronic machines, and table-top mechanisms for preparing folded herbs with high-viscosity ingredients. ientiv.

Vimogi until roztashuvannya obladnannya

The scheme of the hot shop is to remain in place due to its strategic expansion. The cream of this dish is very well served in the immediate vicinity, there is a need for space and a handy operation of a large number of sinks for cleaning kitchen utensils and tableware. The medium-temperature refrigerated cupboard is positioned strategically - opposite the food supply window to the kitchen.

The height at which the room's ceiling is located must exceed 3 meters. To cover walls and other surfaces, light-colored paint is most often recommended. In addition, panels with ceramic veneers are often installed at heights of up to 1.7 m as a subfloor. Materials that are used for processing in a hot shop have sufficient waterproofness, are easy to clean and have a structure that protects against forging.

When organizing his work space, the cook of the hot shop must use equipment that is installed in sections, which allows you to significantly save the working surface and speed up the process of preparing herbs.

Organization of work space

It’s important to consider the dimensions of the kitchen and the equipment of the hot shop can vary in different ways. In rooms with a small area, it is located along the walls and is equipped with strong Primus ventilation. In parallel, there is often a line: a stainless steel table, as well as surfaces for inspection, processing, processing and preparation of products. Great offices, as a rule, have not just one, but a whole series of working places for active cooks. In each case, the zone of space depends on the specifics of the activity. One cook in the hot shop is busy preparing soups. Another - with other herbs or something.

In the area for preparing rare herbs, as a rule, there is a boiler, a saucepan of varying capacity, a frying pan, equipped with a special bath and other equipment, such as small mechanization.

Restaurants pay particular attention to the smoothness of ready-portioned herbs. Having a kitchen cabinet requires the presence of a medium-temperature refrigeration cabinet for cooling food. And also cutting boards, containers for spices, boiling pots and shelving.

Installation of a bathroom for a hot shop

The main benefit to running a workshop for the preparation of hot herbs lies in the efficiency of work space and the creation of the most productive balance, which essentially meets the professional needs of the kitchen depending on its specifics. In connection with this, such approximations are vikoristavuyutsya:

- collection table;

- refrigeration cabinet;

- electronic devices;

- boiler for cooking;

- beaters, etc.

The most productive work staff can help optimize surfaces for greasing, grills, devices that combine processing with steam and high temperatures, ovens, ovens for dough-based products, etc. In general, the hot shop design includes various features that include:

- type;

- flat;

- frequency and intensity of transmission.

The most optimized cooking area will have both tabletop units and great countertops - with a dial. Recently, the main heating equipment in the kitchen has been gas or electric stoves. Today, professional boilers based on steam for preparing all types of herbs, electric surfaces for greasing, special ovens for preparing kebabs, etc. are becoming increasingly popular.

Hot shop safety equipment

The great honor of working in the kitchen lies in the operation of high-temperature appliances, especially respecting, in addition to the highest standards of sanitation, safety equipment. The most extensive of these rules are:

- dismantling, cleaning and washing the equipment is allowed only after it has been connected and when connected to the mains;

- in a container with baked fat (for example, a digester), only dry products are placed, the insertion of which only works directly (“in your own eyes”);

- Containers with dill, the weight of which exceeds 15 kg, are recommended to be removed from the stove in steam.

Knowledge of these rules facilitates regular revisions of the shop floor plan and the introduction of updated fire safety standards. The only thing left is one of the most important minds working in a hot shop. Therefore, those who enter the kitchen must undergo special training. A scheduled check of the knowledge of the rules of other safety is required for skin lesions when the production technology changes and new equipment is acquired.

Ventilation in a hot workshop

The air exchange system in the kitchen of a restaurant or other places is similar to the same device in industrial and residential areas. In this case, the ventilation system in the hot shops of the skin and food industry also has its own peculiarities, as it absolutely lies within its profile. So, for example, in a small cafeteria or one with a small throughput capacity, because of this great shift in professionalism, there is only a table of details and all kinds of subtexts, which is a daily need for a regular circulation This is true, what can’t be said about mortgages for a few dozen places.

A special approach deserves the organization of the ventilation system in the kitchen of the restaurant, in which there is a room for a chicken hookah or a hot tub. Yakshcho, in the way, at the Garyachom shop of PITERSY TsILKO, the NEMPENOTE CHEPTROTROMIN for the pre-person-beating schemes of the organized fingering, then the Great Seryozoic Contain without a folding special proportion cannot be obeyed. The high concentration of hot steam, the products of temperature processing of the furnace - all this requires not just basic air circulation, but heavy ventilation in what looks like a serious engineering system.

Hot shop design

To achieve the most productive results when designing a kitchen, care should be taken when transferring parts. Since the main tasks are to ensure compliance with all technological standards and create maximum comfort for the staff, the project must necessarily include a layout of all equipment.

The kitchen is most often laid out in such a way that the windows are located on the downstairs side. Equipment in this situation can be installed consistently to ensure the most comfortable and effective lancet, in addition to which all processes involving technology transfer are carried out in a proper manner. Of great importance here is the attention to the sanitary and technological rules that apply to such areas, as well as the high degree of importance of product processing procedures. The hot shop layout includes cold and hot water supply, as well as ventilation hoses, hoods and air vents.

Safety during work hours

The main things that can be done to treat specific skin conditions are to come out, first of all, with your arrangement. High-temperature equipment, which may become unsafe, may only be used after proper instruction. Near such a possession, the fire extinguisher indicated on the diagram will inevitably grow. Moreover, the opposite set of tools is liable to break down in the hot area of the skin. It is also necessary to have a box with sufficient volume of sand.

Arrange to transfer the robot to high temperatures (for example, a boiler), and actively work in a hot workshop. In large restaurants, their operation will require a variety of different types of fire, starting with natural coal and ending with heating gas. What is immediately conveyed is the continuation of the same rules when designing an installation and the expansion of such equipment in accordance with all the previous standards.

The width of the passage corridors and the number of exits from the premises, which represent evacuation routes in their entirety, eventually must comply with specific regulations. The scheme of such routes, as a rule, is located in a prominent place in the hot shop, and is also included before the approved plan.

Preparatory procedures

After signing the rental agreement for the premises, which includes the mortgage of the large property, you must provide the landlord with all necessary technical documentation. The warehouse is definitely responsible for the BTI plan, which comes out of this, and it is necessary to start designing and constructing circuits for the hot shop.

To start, you need to contact a qualified fakhist, who will complete all the necessary details. Only after this can the planning of the technology be started, which is followed by the workshop. While you are ready to prepare your chair, you will need to choose a contractor and a specialized contractor. Almost all companies that are engaged in the sale of such equipment, at the same time, are engaged in the development of projects, focusing on specific tasks, such as setting up a manager, planning their own business.

The most widespread mercy for restaurateurs-cobs is the risk of investing in a project without a ready-made technological project. At this time, workers begin to organize electrical wiring and a water supply system without regard to any plan, which, obviously, will lead to the impossibility of ensuring that the work staff is adequately assigned to the tasks.

Expanded benefits

No less important when planning a hot shop is the competent organization of execution of all everyday documents. So, the skin version of the chair is responsible for the mother’s number, which is to confirm those that were confirmed, and the signature of the installation. This approach will help to protect the deputy from various inconveniences. For example, this is how the work is carried out from an irrelevant plan, which has reached the hands of the alarm workers out of ignorance.

The broadest benefit is the search for technology for organizing production on the Internet. An attempt to select the required scheme for a hot shop in Merezha, relying on the similarity of the sphere of activity, leads to the fact that the current restaurateur asks for it from an unknown person and pays a lot of money for it. Removal of the material (as if it were not clear) in this case appears to be absolutely uncontaminated. The main reason for this is the fact that all food preparations (that is, those that have an identical format) are individual: different varieties of producers and variety of production.

Technological project

A technological project is one of the main stages in the creation of a business of any format. His plant includes food supplies to ensure that the hot shop is in compliance with all current standards, planned to be placed in a manner that ensures safety and economy. The technological project makes it possible to eliminate the flow of raw materials and finished products and to work in the hot shop in the most constructive way.

Viral production takes up over 40% of any serious business. Competent arrangement of all necessary nuances helps to avoid significant costs associated with the addition of highly productive and energy-intensive equipment, in which there is no consumption, including the loss of clients.

A competent designer will solve the problem with rational placements in such a way that every centimeter of placement will be as effective as possible. For such work, it turns out that there are cooks who know the peculiarities of cooking and are well-versed in a wide range of products.

ORGANIZATION OF ROBOTICS IN A HOT SHOP

There is a special place in which the working place is arranged so that the technological process of preparing the product can be manually completed.

Perform the following operations:

Shop ties with all the manufacturing and trading premises, which is located near the cold workshop, distributing and washing tableware. At the hot shop, production is sent from all procurement workshops, and it is to be organized in such a manner that you can easily receive from a group of procurement workshops, food supplies, and kitchen utensils.

At enterprises that work behind the systemself-service, The hot shop is complemented by special dispensing equipment next to the sales area: a line of dispensing stands, steam tables, counters. At enterprises withserviced by waiters Can be used to open kitchens or reinforce walls.

Sorry, what is being prepared in a hot workshop,

WATCH FOR THE FOLLOWING SIGNS:

THE COOKER’S WORK IN THE HOT SHOP IS STARTING :

SOUP VILLAGE HOT SHOP

The technological process of preparing first herbs consists of two stages:

Soup and ACCEPTED TO BE CALLED THE FIRST Stravi. The stench is formed from a rare base and various components (garnishes).

Vegetarian;

ON BROTH (KISTKOVIY, M'YASOKIYSNIY, RIBNIUM, Z BIRD);

ON THE TYPE OF MUSHROOMS, VEGETABLES, FRUITS;

ON MILK;

ON KVASI;

WITH FERMENTED MILK PRODUCTS (KEFIR, SORKED VASH).

PZ t SERVE - HOT 75*C – 80*C; COLD 10-14 * C;

ALLOWANCE STANDARDS: 250, 300, 400, 500G;

CLASSIC TECHNOLOGICAL SCHEME ADVANCED

ORGANIZATION OF THREE WORKERS:

At work, cooks are busy Cabin: electronic waggons, a set of cook's three knives, hot shop equipment, detailed boards. The cook's work station may be equipped with a stable seasoning.

For a wide range of soups, a set of soup cup products may include: salted cucumbers, cibul, greens, olives, black olives, lemon, croutons, etc.

The technological line of a hot shop for preparing soups can include:

Virobnichi tables;

Kharchovy boilers;

Electric boilers;

The drive is universal;

Vegetable cutting machine or kitchen processor;

In this part of the hot shop, broths, soups, side dishes, licorice herbs, etc. are prepared.

JUDGMENT VILLAGE OF THE HOT SHOP

The separate sauce is intended for preparing other herbs, side dishes and sauces. To carry out various processes of thermal and mechanical processing of products, the work place is equipped with a variety of utensils, tools, and equipment.

THE COOKER'S WORKFUL PREPARATION OF GARNISHES OF VEGETABLES, GREATS AND PASTA VIROBIAS, THE TECHNOLOGICAL PROCESS IS FOLLOWED BY THE FOLLOWING OPERATIONS:

The technological line of the hot shop for the preparation of other herbs and sauces may include:

Electric frying pans;

Deep fryers;

Hot stove, convection oven, combi oven;

Marmite for preserving food while it's hot;

The tables are refrigerated;

Virobnichi tables;

Gas and electric stoves;

Grills, hot surfaces;

Kitchen processor;

Viral tables from a washed-out bath;

In this part of the hot shop, all other herbs, vicor and other cuts are prepared using heat treatment (lubricating, boiling, poaching, extinguishing, baking, boiling, roasting and bringing the herbs to readiness).

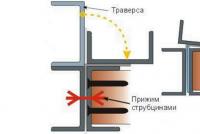

Working place for boiling, sautéing, poaching and baking Products are organized in a number of operations at the same time by cooks. With this method, heat treatment (electric ovens, ovens for greasing or convection ovens, electric frying pans) is grouped according to the level of ease of transition of cooks from one operation to another. Additional operations take place on sampling tables installed parallel to the thermal line. Thermal control can be installed not just along the line, but in an insular way.

HOT SHOP TABLEWARE:

stovetop boilers -20l

boilers for steaming with a grate - insert

pots from 1 to 10 liters

saucepans with a heavy bottom for 2 to 10 liters

metal sheets and chavun pans for greasing meat, poultry, fish, vegetables

small and medium frying pans with a handle for greasing mlints, mlintzes, preparing omelettes.

frying pans for egg glaze

HOT SHOP INVENTORY:

wines

fun

cook's fork

metal and wooden blades

sieves, drushlyak, shenua for processing the broth

skimmer

pouring spoons, sauce spoon

The hot shop is designed for all public catering enterprises, regardless of the local area, including the halls for serving residents.

Hot shop for the preparation of hot herbs, snacks and desserts for sale in the halls, as well as culinary preparations for sale in culinary stores.

The hot shop can be designed on ground surfaces with windows near the courtyard façade. The workshops are located on the same level as the halls. Due to the fact that there are a large number of halls that are laid out on different surfaces, the workshop is designed on the surface where the hall with the largest number of spaces is located. On other surfaces equipped with dispensers, the finished culinary products are transported using a special cord (sometimes a number of hot and cold workshops are designed).

Guild workshops are hand-produced one with one, as well as with other premises: washing tableware and kitchen utensils, preparation and green processing workshops (where the enterprise processes processed food products) and meat and mushrooms. We will run workshops (when working on raw materials) , a culinary store and warehouse premises. It is important to maintain the hot and cold workshops manually in connection with the distribution areas. When serviced by waiters, the shops adjoin directly to the dispensing area, when self-service - to the bays, where the distribution lines are located.

The hot shop is equipped with thermal, mechanical, refrigeration and other equipment. The arrangement of equipment is linear-group, which allows you to place it anywhere with technological processes. Additional equipment is installed in independent lines, which are extended in parallel to the thermal control lines.

Mechanical equipment in a hot shop may be enhanced by the provision of manual maintenance of all technological lines.

The temperature behind the scientific organization should not exceed 23°C, which is strengthened by tidal ventilation (wind speed 1 - 2 m/s); The water content is 60 – 70%. To reduce the flow of infrared exchanges that appear to be heated surfaces for lubrication, the area of the stove is 45 - 50 times less than the area of the substrate. The mode of operation of the hot shop lies in the mode of operation of the enterprise (sales floor) and forms of release of finished products. In order to successfully run the manufacturing program, workers in the hot shop must begin work no later than two years before the opening of the sales floor. The quantity of cooks in the skin section is determined by the ratio of 1: 2, while the quantity of cooks in the soup section is less. In hot, low-pressure workshops, this type of work is usually absent.

The parts of the robot in the hot shop are very diverse, there are cooks of different qualifications working there. It is recommended for the career of cooks in the hot shop: VI category – 15 – 17%, V category – 25 – 27%, IV category – 32 – 34%, III category – 24 – 26%.

In the kitchen there are stove-top boiling pots, stove-top saucepans, saucepans, boxes, boxes of graters for boiling fish, frying pans, leaves and sheets, spatulas, paddles, scoops, skimmers, chumichkas, crushers, etc. made of carbon steel, stainless steel, aluminum. The capacity of stove-top boilers made from sheet steel is 20 to 75 liters, the height of boilers is from 34 to 50 cm, the diameter is 27.5 to 44 cm. Boilers made from carbon steel are forced to reliably bend. The capacity of aluminum boilers is from 10 to 50 l, the bottom diameter and height of the cylinder is from 24 to 40 cm. For boiling products in the boiler, steam the insert of the mesh (insert), which is made from sheets. They became with broken openings in the walls and bottom. Legs are welded to the bottom of the insert mesh so that there is no gap between the bottom of the mesh and the bottom of the boiler, and handles are riveted to the upper edge of the mesh. The size of the insert screens is similar to the size of stove-top boilers.

Slab pots are made from carbon steel, aluminum, and stainless steel. The pots of carbon began to tin. The capacity of the saucepans is 1 to 8 liters, their diameter is 12 to 25 cm, height is 9 to 15 cm. Oval-shaped saucepans are set with a head for stewing meat and game.

The saucepans are shorter in height than saucepans. The smells are made from steel, aluminum and vicor for boiling, poaching, slaking and sautéing. Sauté pans come in different sizes, shapes and capacities (from 1.5 to 6.5 l). Carbines most often come in a rectangular shape with rounded ends. The length is 36-50 cm, width 25-33 cm, height 17-22 cm, capacity 25-35 l.

Cooking fish in carbines is carried out on special inserts. Carabiners, made of carbon steel, are tinned with tin.

Chavunna pans are produced in different diameters - from 12.4 to 37.8 cm. The diameter of steel pans ranges from 10 to 40 cm, aluminum pans from 14 to 26 cm. The thickness of chavunna pans is 2.5-3 mm , steel 1-1.5 mm , aluminum pans 2 mm.

Sheets and confectionery sheets are produced in various sizes from sheet steel, sheet copper and stainless steel. The widest steel sheet is 65 cm long, 50 cm wide, 2 cm high. Primary sheet dimensions: 65 cm long, 50 cm wide.

Blades and rainbows for mixing soups, porridges, and purees are also made from hard wood - beech, birch. Their length is 0.3 to 1.5 m. The scoops are made of stainless steel. The handles of the scoops are made of wood. Scoop capacity 2-3 l.

The skimmers are made of tinned steel, stainless steel or aluminum. The diameter of the noise disc is from 14 to 35 cm. Chumichki are stamped from carbon steel or aluminum. The chumichki are steely to tinker. Their capacity is 0.25 to 0.6 l.

The crushers are made from tinned steel or aluminum. Capacity of drushlyaki is 2 to 7 l. Tools for cutting meat

GOU NVO PU No. 63 KK

Letter qualification for the profession “Cook, confectioner”

"Organization of work in a hot shop

(Sauce branch)"

Vikonala: study group P-31

Zhingel Olena Evgenivna

Reviewer: vikladach

special disciplines

for the profession "Cook, confectioner"

Khalimova Olena Petrivna

Art. Denska

2011 – 2012 initial period

Zmіst.

Introduction………………………………………………………… …….…….story. 3

I. Organization of work in the hot shop (sauce department)……….……..stor. 4

1.1 Organization of work in the hot shop……………………………………. 4

1.2 Equipment, utensils and equipment for the hot shop…………………side. 8

1.3 Organization of work places………………………………………………………………. .Stor. 12

1.4 Organization of work in the hot shop……………………………………………………….p. 15

II. Rozrakhunkova part

2.1 Menu plan for a comprehensive meal at the student’s idalni.…………stor. 16

2.2 Package for storing goods for 50 servings……………………………..p. 17

2.3 Ordering of the completed list………………………………………. 21

2.4 Folding and removal of products…………...p. 22

Conclusion…………………………………………………………….…side. 23

List of references………………………………… …………………... side. 24

Addendum…………………………………………………………………… side. 25

Entry

Hedgehog is the basis of human life. Because of how people want to eat, their health, mood, and productivity are preserved. Well, the food of the people is not less special, but it is huge on the right. The French physiologist Brmat-Savarin should say: “Creatures are present, people are there, reasonable people are able to grub.” “Make a meal” doesn’t mean anything good for your hunger. The cleverness of food conveys to the wiser, deader, the same food, then the culture of food. This very difficult food of science and culture must be read, read at a young age, before people become ill from the overwhelming food. So the kitchen on the right is even more serious and resembles a crazy setup.

In this huge restaurant, one of the most important places is the preparation of food and the hot shop, which can be called the heart of the business.

In the hot workshops of great enterprises for the preparation of first herbs, a soup department is organized, and the preparation of other herbs, side dishes, and sauces is a sauce department.

Meta of my work: learn how to work in a sauce department in a hot shop, learn how to compile technological documentation.

The relevance of the thesis lies in the fact that the municipal food industry is in great demand, as new technologies and new everyday equipment are quickly appearing.

To compile the work, I used handbooks for NOOs, magazines, collections of recipes, periodicals, and Internet resources.

- Organization of work in the hot shop (sauce department).

- 1.1 Organization of work in the hot shop.

The hot shop occupies the central location of the huge food industry. At times, if a hot shop is served by a number of trading floors, spread out on different surfaces, it is completely spread out on the same surface as the trading floor, so that there is a large number of seating areas. On all other surfaces there are dispensers with a plate for greasing portioned ingredients and marmette. The supply of these distributing finished products will be ensured with the help of warehouse workers.

The hot shop is due to a close connection with the procurement departments, storage areas and a close connection with the cold shop, distribution and sales area, and kitchen utensils.

The products that are prepared in a hot shop are divided into the following basic signs:

a type of dried cheese - from potatoes, vegetables and mushrooms; from cereals, legumes and pasta virobіv; z yaєts ta siru; from fish and seafood; from meat and meat products; from poultry, game, rabbit and so on;

method of culinary preparation - boiled, stewed, stewed, greased, baked;

the nature of the food - soups, other herbs, side dishes, drinks, etc.;

important - for children's, school food and other;

consistencies - rare, thick, thick, puree-like, viscous, loose parts.

The work of the hot shop is obliged to comply with the power of national standards, galusa standards, enterprise standards, collections of herbal recipes and culinary herbs, technical minds and the search for technological instructions and maps, technical and technological maps for the implementation of the Sanitary Rules for public catering establishments.

The hot shop's food production program is based on an assortment of herbs that are sold through the sales area, an assortment of culinary products that are sold through buffets and food outlets (cooking shops, trays).

Microclimate of a hot shop. The temperature behind the scientific organization does not have to exceed 23 ° C, which is strengthened by tidal ventilation (the velocity of the air is 1-2 m/s); The water content is 60-70%.

To change the flow of infrared exchanges, which are seen as heated surfaces for lubrication, the area of the stove is 45-50 times less than the area of the substrate.

The mode of operation of the hot shop lies in the mode of operation of the enterprise (sales floor) and forms of release of finished products. In order to successfully run the manufacturing program, workers in the hot shop must begin work no later than two years before the opening of the sales floor.

The hot shop is divided into two specialized departments - soup and sauce making. In the soup section, the preparation of broths and herbs is involved, in the sauce section, the preparation of other herbs, side dishes, sauces, and hot drinks.

Zagalne planuvannya hot shop. (Addendum No. 1).

Separate sauce.

The separate sauce is intended for preparing other herbs, side dishes and sauces.

The work of the cooks in the sauce department begins with an awareness of the production program (menu plan), a selection of technological maps, and clarification of the number of products necessary for the preparation of herbs.

Then the cooks get the ingredients, prepare the ingredients, and select the dishes. At the restaurant, the pastries are greased, baked and ready for preparation; Labor-intensive herbs that take a lot of time to prepare (stews, sauces) should be prepared in small batches. At other enterprises, during mass production, even if any product is prepared, it is necessary to lubricate other ingredients (cutlets, beefsteaks, entrecotes, etc.) to be sold with a stretch of 1 year; other herbs boiled, stewed, stewed – 2 year, vegetable side dishes – 2 year; porridge roses, stewed cabbage - 6 years; hot drinks - 2 years. In case of vine cases, it is necessary to refrigerate and store at a temperature of 2-6°C for no more than 18 years, subject to the required sanitary rules for the preservation of hedgehogs. Before sale, the liquid is cooled, checked and tasted by the head of the vibrator, after which it is obligatory to undergo thermal processing (boiling, greasing on the stove or in a lubricating dish). The term of implementation even after this thermal treatment does not have to exceed one year. It is necessary to mix the surplus from the previous day or from the same day, or from the previous day.

It is protected from the coming day in the hot sauce department:

Mlintsi with meat and cheese, rubans with meat, poultry, fish;

sauce;

omelet;

potato puree, boiled pasta sprouts.

In cheese and grub products, which are used for the preparation of herbs, instead of potentially harmful substances for health, chemical and biological substances (toxic elements, antibiotics, pesticides, pathogenic microorganisms, etc.) .) is not guilty of exceeding the standards established by medical-biological and sanitary regulations product viability standards. lively This is specified in GOST R 50763-95 “Gromadske food. Culinary products sold to the population. Deep technical minds.

In sauce departments, it is important to organize work areas depending on the type of heat treatment. For example, a working place for lubricating and sautéing products and beverages; other - for boiling, stewing and poaching of products; third - for preparing side dishes and porridge.

- Equipment, dishes and equipment for the hot shop.

Thermal and mechanical equipment must be selected in accordance with the equipment standards for the equipment of public catering enterprises.

The main equipment in the sauce department is a stove, a greasing dish, an electric frying pan, a deep fryer, as well as herb boilers, a universal drive. Stationary herbal boilers are set in a sauce department in large workshops for boiling sheep and cereal side dishes.

Kebabs are installed in hot shops of specialized enterprises and restaurants. The enterprises use sausage cookers, egg cookers, casserole cookers, etc.

Accelerated cooking may be achieved by stagnant high-frequency devices. In NHF devices, the heating of finished products allows the entire volume of the product to be penetrated to a certain depth by the power of electromagnetic circuits.

To prepare baby herbs, place a steamer in the sauce section.

The installation of the sauce department can be grouped into two or three technological lines.

The first line is intended for thermal processing and preparation of herbs from prepared products from meat, fish, vegetables, as well as for the preparation of side dishes and sauces in stovetop dishes. The line consists of a sectional modular equipment and includes a lubricated cooker, stove, electric frying pan, and deep fryer. Restaurants throughout the entire line install the same marmite, designed for short-term preservation of other herbs in a hot oven (Appendix No. 2).

The other line is designed for additional operations and includes sectional modular tables: a table with a built-in wash bath, a table for installing small mechanization devices, a table with a hot water chilled, and shafoy (in restaurants).

Meat, fish, and processed vegetables are cooked on the roasting tables until heat-processed. A vibrator table with a hot pot that is cooled and a savory pan is used in restaurants for portioning and arranging the herbs.

The third line is organized in large hot shops, where stationary pickling boilers are installed for brewing side dishes. This line includes sectional modular boilers with functional containers, work tables for preparing products for cooking (sorting cereals, pasta, etc.), a bath for washing side dishes. In restaurants, where it is important to prepare folded side dishes in small quantities, instead of stationary herbal cauldrons, use stove-top dishes. To grease potatoes (fry, pie and in), use deep fryers type FESM-20, FE-20.

Place the dishes in a saucepan (Addendum No. 3):

stovetop boilers with a capacity of 20, 30, 40, 50 liters for boiling and sautéing meat and vegetables; cauldrons (boxes) for boiling and poaching fish whole and in lanks;

boilers for steaming dietary herbs with a grate insert;

saucepans with a capacity of 1.5, 2, 4, 5, 8 and 10 liters for preparing small portions of boiled, stewed other herbs, sauces;

saucepans with a capacity of 2, 4, 6, 8 and 10 liters for sautéing vegetables, tomato puree. While standing in front of the cauldrons, the saucepans are washed with a thick bottom;

sheets of metal and large chavun frying pans for frying prepared meat, fish, vegetables, poultry products;

small and medium frying pans with a handle for greasing mlintzes, mlintzes, preparing omelettes;

frying pans with 5, 7 and 9 middles for preparing egg glaze in large quantities;

chavunny frying pans with a press for greasing the chicken-tutyun and in.

The inventory of the hot shop is shown in Addendum No. 4.

Stock up on the inventory: wreaths, oars, cook's vipers (large and small); Gurkit; spatulas for mlintz, cutlets, rib; stand for processing the broth, sieves, ladles, skimmers, skewers for greasing kebabs.

At the work place of the cook, for lubricating and sautéing the products, vikoryst stoves (PEMM-4, TLM-0.51, PE-0.51Sh, PE-0.17, PEMM-4ShB, APN ta in), frying racks (IZhSM-2K ), selection tables and transfer racks. In restaurants, where the assortment of herbs is varied and they prepare herbs, deep-fried (Kiev cutlets, fried fish, etc.), over an open fire (grilled sturgeon, grilled poultry, etc.), turn on the electric grill on the heat line (GE , GEN-10), deep fryer (FESM-20, FE-20, FE-20-0.1). Place the prepared mixture in a strainer in a deep fryer with hot fat, then prepare the mixture using a strainer or a slotted spoon, placing it on a saucepan to drain off the fat. If the assortment of herbs includes kebabs, then organize a special working place that comes from the roasting table and the ShR-2 kebab oven.

Workplaces for boiling, sautéing, poaching and baking products are organized by the cooks in a number of operations at the same time. With this method, heat equipment (stoves, greasing ovens, electric frying pans) is grouped with the difference in the ease of transition of cooks from one operation to another. Additional operations take place on sampling tables installed parallel to the thermal line. Thermal control can be installed not just along the line, but in an insular way.

Boil porridge and pasta for baked herbs in stove-top boilers. Place the masa prepared for baking on sheets and place it near the shafi for greasing until ready. Stew food in cauldrons or electric frying pans.

At the work place of the cook, who prepares side dishes from vegetables, grains and pasta grains, the technological process consists of the following operations: sort the grains on the bread table, rinse, then boil them at stationary or on stove boilers.

For boiling and quick removal of the finished product from stationary boilers, insert mesh inserts made of stainless steel. Place the boiled pasta on a plate and rinse.

The selection of stove-top boilers for boiling porridge of varying consistency is carried out in a volume that takes up 1 kg of cereal at a time with water (Addendum No. 5). To prepare sauces at work, use pickling pots if you need to prepare a large batch of sauces, or use pots of different capacities when preparing a small amount of sauces. To strain vegetables and process vikory broths, use sieves of various shapes or strainers. The main sauces (red and white), as a rule, are prepared for the whole day, and secondary sauces for 2-3 years of sales of herbs on the sales floor.

1.3 Organization of work places.

A work place is a part of the manufacturing area where the worker carries out various operations involving his own equipment, utensils, equipment, and tools. Workplaces in the municipal food industry have their own characteristics depending on the type of work, its workload, the nature of the manufacturing operations, and the range of products that are produced.

The area of the workspace is sufficient to ensure rational placement of equipment, the creation of safe minds, as well as the manual handling of inventory and tools.

Workplaces in the workshop are transformed in the technological process.

Workplaces can be specialized or universal. p align="justify"> Specialized work stations are organized at large enterprises, when a worker completes one or many similar operations throughout the working day.

In medium and small enterprises, universal work stations are important, where a number of different operations are carried out.

The organization of work places takes into account the anthropometric data of a person’s body, i.e., the depth, height of the work place and the front of work of one worker are determined based on the growth of a person (Appendix No. 6).

During the development of the sectional modular equipment, the capital factor was re-insuranced.

The dimensions of the professional possession of the culprit should be such that the body and hands of the worker are in the most favorable position.

As you have demonstrated the organization of the cook’s work place, stand on the top of the table to accommodate the stock of utensils that may exceed 1750 mm (Addendum No. 7). The optimal distance from the base to the middle line is 1500 mm. This area is the most tame for the cook. It’s very handy if the table contains storage for equipment and tools. At the bottom of the table there are racks for dishes and cutting boards.

Sectional modular tables for small mechanization, with a hot pot that cools, and a cooking pot. For kitchen tables and bathtubs, bottom wooden shelving is installed. For the handiness of the robot, the height of the table should be such that the distance between the doctor’s elbow and the surface of the table does not exceed 200-250 mm.

The minimum visibility of the object becomes 18°. In this sector, in my opinion, there are those who are guilty of paying mittevo. The point of effective visibility is to exceed 30°. The average person has a view of 120°, so the table does not have to overextend 1.5 m.

Sufficient space in the working area prevents potential injuries and ensures proper handling during operation and repair. It is recommended to adhere to the permissible heights when placing equipment (in m):

Between two technological lines of non-mechanical

possession with bilateral expansion of robotics

place and double lines up to 3 m…………………………………….……..1,2

over 3 m………………………...1.5

Between the wall and the technological line

non-mechanical possession……………………………...0.1-0.2

Between the wall and mechanical equipment…………….. 0.2-0.4

Between the wall and thermal control ………………………...0.4

Between the technological line of thermal control

and distribution line…………………………………………………………………..1.5

Between the working fronts of thermal and non-mechanical

Installation………………………………………………………1.5

Between the working fronts of the boiler sections ……………2.0

Between electric boilers that are installed

in line……………………………………………………………… 0.75

Between the technological lines of equipment,

what does heat see……………………………………………………….1.5

Between the wall and the work place of the vegetable cleaner.

in the sheep shop……………………………………………………………… ……… 0.8

The skin working area must be provided with a sufficient number of tools, equipment and utensils. Dishes and equipment must be selected according to equipment standards depending on the type and severity of the activity. Before the production of inventory, the following advantages are presented: value, reliability in work, aesthetics, etc.

Sanitary and hygienic conditions for equipment, utensils and tools are indicated by SP and SanPiN, therefore utensils, equipment and tools must be prepared from unsafe and unsafe for human health. a great variety of materials.

1.4 Organization of work in the hot shop.

The parts of the robot in the hot shop are very diverse, there are cooks of different qualifications working there. It is recommended at the stage of professional development of cooks in the hot shop: VI category – 15-17%, V category – 25-27%, IV category – 32-34% and III category – 24-26%.

The production team of the hot shop also includes kitchen utensil washers and kitchen cleaners.

A cook of the VI rank, as a rule, is a foreman or a senior cook and is responsible for organizing the technological process in the workshop, including maintaining the output of herbs. We follow advanced technologies for the preparation of herbs and culinary herbs, prepared portions, branded, banquet herbs.

A 5th grade cook prepares and prepares pastries that require the greatest amount of culinary preparation.

etc...................