Chavunni hatches are important DERZHSTANDARD 3634 99. Chavunni hatches. Yeast virobu control

GOST 3634-89

Group Zh21

NATIONAL STANDARD OF SPILKI RSR

CHAVUNI HATCHES FOR INSPECTION WELLS

Technical minds

Cast-iron access manhole covers

Technical requirements

Date of introduction 1989-07-01

INFORMATION DATA

1. Divided and introduced by the State Committee for Architecture and Places of the Derzhbud SRSR

VIKONAVTSI:

Y.M. Sosner (kerivnik temi); P.I. Kruglyakova; L.B.Kogan, Doctor of Engineering. sciences; O.V. Ostroverkhov, Ph.D. tech. sciences; A.P. Chekrigin; L.S. Vasilyeva

2. CONFIRMATIONS AND INTRODUCTIONS BY THE RESOLUTION OF THE SRSR State Budgetary Committee dated 04/06/89 No. 62

3. VZAMIN GOST 3634-79

4. COMPLETE REGULATIVE AND TECHNICAL DOCUMENTS

Number of paragraph, subparagraph, |

|

GOST 882-75 | |

GOST 1412-85 | |

GOST 2283-79 | |

GOST 3282-74 | |

GOST 6521-72 | |

GOST 7293-85 | |

GOST 7338-77 | |

GOST 9347-74 | |

GOST 14192-77 | |

GOST 15150-69 | |

GOST 21929-76 | |

GOST 23711-79 | |

GOST 26358-84 | |

GOST 26645-85 |

This standard applies to round manholes and inspection wells along the water supply and sewerage lines.

1. TECHNICAL VIMOGS

1. TECHNICAL VIMOGS

1.1. Hatches and repair inserts must be manufactured in accordance with the required standard for working chairs, hardened in accordance with the established procedure.

1.2. Main parameters and dimensions

1.2.1. Type, the mass and area of shutdown of hatches, depending on the minds of operation, is shown in the table.

Masa of hatch parts | ||||||

Name | Galuz zastosuvannya |

|||||

cor- | cry- | cor- | cry- | |||

Light hatch | Near the green planting zone |

|||||

Important hatch | On Zagalny cars |

|||||

TM | Important | 50 | 45 | 50 | 43 | On highways |

R | Remontna | 35 | For hatch bodies of type T |

|||

1.2.2. The main dimensions of the hatches correspond to those shown in Fig. 1-4.

Type L

Damn. 1

1 – cap;

2 – body;

3 - assignment of the right hand

5 – trademark

1.2.3. The level of the designated hatch can be formed from a designated type, called an engineering seal, for any purpose, that is designated to the standard. The names of engineering lines for various purposes of the hatch are: - water supply; G – fire hydrant; K - pobutova and virobnycha sewerage; D – plank sewerage.

Butt of the mental designation of a light hatch on the water supply line:

LV GOST 3634-89;

the same important main hatch for the plank sewerage system in Vikonanny P:

TMD P GOST 3634-89;

the same repair inserts for hatches of types T and TM for all types of engineering measures:

R GOST 3634-89.

Type T

Damn. 2

1 – cap;

2 – body;

3 - assignment of the right hand

standard and release; 4 – assigned to the type of hatch;

5 – trademark

1.3. Characteristics

1.3.1. The configuration of the ribs on the outer surface of the covers of hatches of types T and TM can be either quill-like (Vicon I, Fig. 2) or tangential (Vikon P, Fig. 3) in shape.

1.3.2. It is allowed that the external contour of the top body of hatches of types L and T be made square of the same size, with the guts placed under the lids diagonally.

1.3.3. Hatch bodies of all types, covers and repair inserts are made from a chavun no lower than grade SCH15 according to GOST 1412.

Hatch covers of type TM are made from chavun no lower than grade VCh45 per GOST 7293.

1.3.4. The elastic gasket is made from gum with a hardness of at least 40 units. according to Shore A.

Brackets for securing the elastic gasket in the groove of the hatch body or repair insert are prepared using stitches 65G-N-1, 0x10 according to GOST 2283. It is allowed to stitch stitches of 0.8-1.2 mm of the same brand.

1.3.5. Hatch inserts and repair inserts comply with GOST 26358.

On the surface of the forks, shells with a diameter of more than 10 mm and a depth of more than 3 mm are allowed, which occupy more than 5% of the surface of the forks. On the lower supporting surface of the hatch bodies, when they are poured into an open form, slag inclusions and inflows are allowed, which occupy no more than 10% of the buried surface area.

Type TM

Damn. 3

1 – cap;

2 – body;

3 – elastic gasket; 4 - bracket;

5 - assigned to the standard for the release;

6 – assigned to the type of hatch; 7 – trademark

1.3.6. Tolerances for hatches and repair inserts are as follows: weight – 11th accuracy class, dimensions – 10th accuracy class according to GOST 26645, with the exception of the markings on the seats.

1.3.7. The hatch cover fits snugly against the supporting surface of the body.

The flatness tolerance of the supporting surface of the hatch cover, as well as the supporting surfaces of the body and the repair insert, must not exceed 2 mm.

1.3.8. At the top of the manholes, in addition to the water supply manholes, there may be openings for collecting samples of gas contamination of the manholes.

1.3.9. The hatch cover, when tested for mechanical strength, is subject to vibration stress: type L - 30 kN (3 tf), type T - 150 kN (15 tf), type TM - 250 kN (25 tf).

1.4. Completeness

1.4.1. The hatches are finished completely.

The kit includes:

body – 1 piece;

cover – 1 piece;

passport – 1 approx. (For a batch of hatches).

To the warehouse, the kit type TM, designated, includes:

elastic gasket – 1;

bracket – 5.

1.4.2. The repair insert is prepared on the additional basis.

The repair insert kit includes pcs.

building 1;

elastic gasket – 1;

bracket – 5.

Type P

Damn. 4

1-body; 2-elastic gasket; 3-bracket

1.5. Markuvannya

1.5.1. On the upper flat surface of the hatch cover, surrounded by a ring rib, there is a clear hatch marking, the manufacturer's trademark. For any type of hatch and engineering seal, extend along the axial line that connects the lug.

1.5.2. Letters on the hatch cover, which indicate the hiring of engineering measures, due to dimensions, mm:

height - for hatches of types T and TM - 140±10, type L - 80±10

width - for hatches of types T and TM - 100±10, "L - 50±10"

The thickness of the linear letters is no less than 15 mm. The dimensions of other marking signs are determined by production companies.

1.5.3. Transport markings should be wrapped in tarpaulin, which does not wrinkle, in accordance with GOST 14192 on plywood tags, which are attached with a dart with a diameter of at least 1 mm to the skin area (package).

1.6. Package

1.6.1. The packaging of hatches is carried out in accordance with GOST 21929.

1.6.2. The bags are molded around the bodies and covers of hatches placed horizontally on two wooden beams. The leather package consists of 10 bodies or 10 hatch covers. Schemes, sizes and masses of packages are indicated in the supplement.

The dimensions of the packages may be changed depending on the circumstances.

The tying of the hatch bodies is carried out in several places through their central opening, and the hatch covers - from buried waste.

To form the packages, use a steel drill with a diameter of 6-8 mm according to GOST 3282. The ends of the drill are ringed.

2. PRIYMANNYA

2.1. Catch the hatches in batches. The batch is used to replace the hatches from one melt.

2.2. Hatches must be subject to proper and periodic testing.

2.3. During initial testing, it is necessary to check the external appearance of the covers, housings and repair inserts of hatches and the mechanical quality of the covers. Changes in appearance indicate a leather hatch, changes in mechanical quality - only hatch covers at a rate of 3%, and not less than two hatches per batch.

2.4. If the verification results are unsatisfactory during the initial testing, it would be desirable to carry out a second verification of one of the indicators for this indicator of the second number of hatches. The results of repeated verification are extended to the entire batch and remain residual.

2.5. During periodic testing, check the dimensions, the mass of hatch parts, the flatness of the cover at least on three hatches that have undergone proper testing, at least twice per river, and also For skin replacement of technological equipment.

2.6. The owner has the right to carry out control verification of the quality of hatches to any possible standard, in order to establish procedures for the selection of materials and control methods.

2.7. Hatches, which are of a standard quality, must be accompanied by a passport, from whom you indicate:

the name of the ministry and department of the pharmaceutical enterprise;

naming a trademark of the virobnik;

the mind is assigned to the virobu;

batch number;

number of viruses;

warranty term of operation;

stamp and date taken by technical control;

according to the standard.

3. CONTROL METHODS

3.1. The dimensions of covers, bodies and other parts of hatches are checked using universal and special measuring tools, as well as templates.

3.2. The hardness of gum beyond Shore A is designated as a fit according to GOST 263.

3.3. The weight of the covers, hatch bodies and repair inserts is verified on commercial items within the limits of no more than 500 kg according to GOST 23711.

3.4. The flatness of the supporting surface of the hatch cover, the supporting surfaces of the body and the repair insert is checked with a set of feelers according to GOST 882.

3.5. Testing of the hatch cover for mechanical integrity is carried out on a press, which will ensure the necessary forces and with a pressure gauge with an accuracy class of 0.4 according to GOST 6521. The press is equipped with a steel punch with a diameter of 200 mm, the lower edge of the punch has a radius of rounding of 10 mm.

3.6. To test, install the hatch cover on the press frame, which has an opening with a diameter of 500-600 mm.

Between the punch and the hatch cover, place a ball of cardboard according to GOST 9347 or gum GOST 7338 with a thickness of no more than 3.0 mm.

Press the pressure evenly until indicated and press the lid under this pressure for at least 30 s.

The hatch cover is respected, which has been tested for quality, so that no damage will be revealed.

The crusts that have been seen during testing are allowed to be washed.

4. TRANSPORTATION AND STORAGE

4.1. Hatches can be transported by any type of open or closed transport means.

4.2. Transportation of hatches by motor transport is subject to the rules for transporting items that apply to motor transport.

When transported by road, the hatches do not need to be packaged, in which case the cargo may be uniform and it will be difficult to move the cargo.

4.3. When transporting hatches by cargo transport, certain wagons or platforms may be used to move the wagons to the maximum extent of their space and vantage capacity.

4.4. Cleaning of hatches - according to group Z1 GOST 15150.

5. INSTRUCTIONS FOR OPERATION

5.1. The hatch body is installed horizontally on a prepared concrete base or the masonry is laid out and concreted.

The top of the hatch body during installation is subject to contact with the level of the road surface.

5.2. Hatches on the other part of the street are installed with lugs along the main route of transport. In this case, the type of hatch and the engineering barrier must be installed in front of the vehicle that is collapsing.

5.3. When building up the road surface, install the repair insert.

6. GUARANTEES VIGOTOVTSYA

6.1. Virobnik guarantees the conformity of the hatches to the highest standards for cleaning the minds of transportation, saving and operation.

6.2. The guarantee term of operation is three years from the day the hatches are put into operation, and no more than five years from the moment of product development by the manufacturer.

1 - binding;

2 - place of slinging

Package weight, kg |

|||||||

Text of the document for:

Officially seen

M: CITP Derzhbudu SRSR, 1989

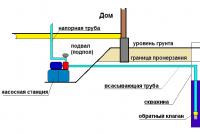

The inspection well hatch is important ( Luke T (S250) K.1-60 ) – this is the manhole body and cover that are installed on the opening of inspection wells for sewerage, water supply and other engineering lines. Important hatches most often get stuck in road and industrial life. Hatch T (C250) K.1.60 is made from a high-quality chavun of a brand no lower than 110. An important hatch is sealed to protect well shafts on motor roads with intense traffic and in industrial zones. The norms and standards for the manufacture of hatches are enshrined in GOST 3634-99.

It is impossible to lift and install the frame of your mass (110) without installing special devices. The need for such a vault is explained by the fact that when they stand on roads with intense flow, the sewer manholes are usually in a static position, and a small leak in the structure threatens the crash of the car. transport. The solid mass of chavun hatch guarantees greater durability over time of use.

Hatch T (C250) K.1-60 is produced with a diameter of 830 mm. The cover of an important hatch type T may have a significant value kN.

Hatch T (C250) K.1.60 has a round shape, a flat body and a flat top or round (so that debris does not collect on the surface),

Traditionally, the covers of chavun hatches are ribbed - this ensures the great value of the hatch and better sealing during the collapse of vehicles. The upper surface of the hatch cover has a curved relief of 3 to 8 mm, often the relief takes the shape of different-looking babies. The ribs on the outer surface of the cover of an important hatch can be either convoluted or tangential in shape.

The cover of the pit hatch can be attached to the body using one or two hinges with a lock, which provides additional protection against unauthorized entry into the pit by third parties. The internal locking devices of the hatch are made of steel grade no lower than St3 with anti-corrosion coatings.

Also, the lid of the important hatch has an opening for collecting gas samples (except water samples). This is due to the elastic gasket between the cover and the body.

Markuvannya virobu

On the surface of the hatch cover, parallel to the axial line, surrounded by an annular edge, there is a marking of the hatch, the direction of its outlet and the trademark of the manufacturer.

The marking of the hatch of an important type lies in the viconn, with numbers and the structural features of the viruses. Number 1 indicates the presence of hatches for underground purposes, 2 - the presence of a locking locking device, 3 - the presence of a cover structure that has been damaged under filling with concrete, 4 - the presence of a device for lifting the cover using a standard vantage mechanism , 5 - hatches with reinforced hull, 6 - hatches with a cover made of two parts, 7 - with a cover hingedly attached to the body, 8 - hatches of square or rectangular shape.

Also, at the top of the hatch, indicate the designated engineering measures of the well that covers the hatch. Names of engineering measures for various purposes of the hatch:

- B – water supply;

- G – fire hydrant;

- K - pobutova and virobnycha sewerage;

- D – plank sewerage.

- TS - thermal measures

- GS - gas barrier

- GTS - miska telephone network.

The level of the designated hatch can be based on the type of hatch, a window or a number of hatches, the overall dimensions of the hatch in centimeters according to the standard. It is also possible to mark the markings with other lettering designations. This is nothing less than the conformity of hatches of ham production to European standards. Thus, the T hatch corresponds to the C250 class; hatch C – class B125, etc.

Let's take a look at the butt of the mental purpose of an important hatch:

- T-type hatch (important);

- C250 - conformity with the European standard;

- Literi – the name of an engineering line;

- The first number is the index of the hatch;

- Another figure is the hole diameter 650mm;

- GOST 3634-99 - reference to the national standard.

Yeast virobu control

Vilivok Luke T (C250) K.1.60 is not guilty of any significant defects or cracks that could affect the quality of the product. Sinks with a diameter of more than 10 mm and a depth of more than 3 mm are not allowed. The cover must fit firmly against the supporting surface of the body - the gap between the cover and the body is no more than 3 mm. The straightness of the supporting surface may exceed 2 mm.

on Priymalno-zdalnyh viprobuvannyakh hatches The external appearance of all covers and hatch bodies is monitored, as well as the mechanical value of the covers (at least 2 hatches from a batch).

Technical passport, who is guilty of obligatory support of the party of chavunnyh hatches, is guilty of notifying:

- naming a trademark of the virobnik;

- markuvannya virobu;

- batch number;

- number of hatches in the party;

- warranty term of operation;

- stamp and date taken by technical control;

- according to the sovereign standard.

Transportation and saving.

Heavy hatches are transported by different types of transport, packed in bags tied with dart. For Luke T (S250) K.1-60, the manufacturer's warranty is extended. Warranty term - 3 years from the day the hatches are put into operation, and no more than 5 years from the moment the product is delivered to the dealer.

GOST 3634-99

INTERSTATE STANDARD

HATCHES OF WONDERFUL WELLS

І DOCUMENTS

ZLIVKOVYKH WELLS

Technical minds

INTERNATIONAL SCIENTIFIC AND TECHNICAL COMMISSION

STANDARDIZATION, TECHNICAL REGULATIONS

І CERTIFICATIONS FROM BUDIVNITSTVI

(MNTKS)

Moscow

Peredmova

1 DISTRIBUTED VAT "Kirovsky Zavod" (Kaluzka region), DP CNS and a group of fakhivts

INTRODUCED by Derzhbud of Russia

2 ACCEPT by the Interstate Scientific and Technical Commission for Standardization and Technical Norms and Certification in Budivnytsia (MNTKS) 2 Br 1999 r.

|

Name of power |

Name of the body of the sovereign government of life |

|

Republic of Armenia |

Ministry of coordination, territorial administration and local activities of the Republic of Virmenia |

|

Republic of Belarus |

Ministry of Architecture and Lifestyle of the Republic of Belarus (Ministry of Architecture and Life of the Republic of Belarus) |

|

Republic of Kazakhstan |

Committee on the right of the Ministry of Energy, Industry and Trade of the Republic of Kazakhstan (Kazbudkomitet) |

|

Republic of Moldova |

Ministry of Environment and Improvement of the Territory of the Republic of Moldova |

|

Russian Federation |

Derzhbud of Russia |

|

Republic of Uzbekistan |

State Committee of the Republic of Uzbekistan for architecture and life (Sovereign Committee of the Republic of Uzbekistan) |

The type of hatch is selected depending on the location of installation.

4.2 Behind the Vikonanny hatches are located:

1 – zagalal meaning ();

2 - with a locking device on them (). The design of the castle building is suitable for living;

3 - what are the roofs of the structure under the filling of concrete class not lower than B30 ();

4 - with a device for lifting the cover using a standard lifting mechanism. The design of the building may be suitable for use;

5 - we will strengthen the hull with anchor bolts or special fillers on the hull (). The design of anchors, rivets and their quantity (at least two) is suitable for consistency;

6 - with a lid, which consists of two parts ();

7 – with a cover, hingedly attached to the body;

8 - with a square or rectangular shape of the cover and (or) hatch body.

4.3 Types, main parameters and dimensions of the handlers, their installation location is indicated. The type of connection is selected depending on the location of installation.

Table 1

|

Type (designated according to EN 124) |

Name |

Outside view D, not mensch, mm |

h, not mensch, mm |

Masa zagalna, dovidkova, kg |

||

|

LM* (A15) |

Lightweight, compact hatch |

Green zone, pedestrian zone |

||||

|

L (A15) |

Light hatch |

|||||

|

W (V125) |

Middle hatch |

Parking lots , sidewalks and walkways, part of the city's parks |

||||

|

T (S250) |

Important hatch |

Moscow highways with intense traffic |

||||

|

TM (D400) |

Heavy trunk hatch |

Main roads |

||||

|

ST (E600) |

Overhead hatch |

|||||

|

Repair insert |

Hatch bodies of types C (B125) and T (C250) during road repair work (with increased roadway height) |

|||||

|

* For underground communications from a deep channel up to 600 mm above the outer surface of the manhole cover. |

||||||

4.4 For Vikonanny, the officers are responsible for:

1 - with a minimum width of the supporting part of the body behind the contour ();

2 - with a minimum width of the later support part of the body, which adjoins the road curb ();

3, 4, 5 - with the minimum width of the later supporting part of the body, adjacent to the curb of the road, one right (side 2) or left (side 3), or both (side 4) short sides;

6.7 - with the minimum width of the short supporting part of the body, which adjoins the road curb (line 5), or with both short sides (line 6);

8 - with a single body under two grilles ();

9 - with strengthening of the body, for which the rest is equipped with anchor bolts or special lugs on the body (). The design of anchors, tides and their quantity (at least two) is suitable for compliance;

10 - with burrs, hingedly attached to the body.

Table 2

|

Type (designated according to EN 124) |

Name |

Living area S, not less, m2 |

Depth of installation of the cover at the body h, not mensch, mm |

Masa zagalna, dovidkova, kg |

|||

|

D(A15) |

Doshchepriymach maliy |

0,05 |

Pilgrimage zone |

||||

|

DB1* |

The Great Doshchepriymach |

0,075 |

Parking lots and passages of some of the local highways |

||||

|

DB2** (V125) |

0,15 |

||||||

|

DM1 |

Doshchepriymach magistralny |

0,075 |

Main roads with intense turbulence |

||||

|

DM2 (S250) |

0,15 |

||||||

|

DS1 |

Doshchepriymach nadvazki |

0,075 |

Zoni vysokih navantazheni (airfields, docks) |

||||

|

DS2 (D400) |

0,15 |

||||||

|

On roads (airfields) during late schila: |

|||||||

|

* DB1 - i o£ 0,005; |

|||||||

|

** DB2 - i o>0,005. |

|||||||

4.5 The proper designation of the hatch or the doschepriymach must be formed from the words “Hatch” or “The doschepriymach”, this type, Vikonanny or many Vikonan, the overall dimensions of the manhole in centimeters and according to its standard.

In addition, prior to the designation of the hatch, designated engineering measures are introduced for the following purposes of the hatch: - water supply; G – fire hydrant; K - pobutova and virobnycha sewerage; D – board sewerage, TZ – thermal boundary, GS – gas boundary, GKS – cable boundary (including GTS – subject to weather conditions).

Use your brains:

light hatch for water pipes with a square cover and a manhole size of 60´ 60 cm

Luke L (A15) - St 8-60´ 60 GOST 3634-99;

middle hatch for sewerage with a locking device and a hole diameter of 60 cm

Hatch S (B125) – K.2-60 GOST 3634-99;

repair insert for an important hatch, be it any kind or use of engineering measures with a hole diameter of 60 cm

Repair insert R.T-60 GOST 3634-99;

Great Viconnian hitchhiker 2 with a minimum width of the later support part of the body, which contacts the road curb with a manhole size of 30´ 50 cm for roads with late developmenti o<0,005

Doshchepriymach DB1 (V125) - 2-30 ´ 50 GOST 3634-99.

5 Technical benefits

5.1 Hatches of inspection wells, repair inserts and access points are prepared according to the required standard for working chairs, hardened in the established order.

5.2 Characteristics

5.2.1 Injections are free from defects that reduce their value. The plugs may comply with GOST 26358.

On the surface of the forks, shells with a diameter of more than 10 mm and a depth of more than 3 mm are allowed, which occupy more than 5% of the surface of the forks. Cracks are not allowed. Slag inclusions are allowed on the lower supporting surface of the housings, the inner surfaces of hatch covers and grouts, which occupy no more than 10% of the underground surface area.

5.2.2 Tolerances of forks must comply with: dimensions - not lower than the 10th accuracy class according to GOST 26645, weight - 11th accuracy class.

5.2.3 The upper surfaces of hatch covers of all types shall be embossed. The height of the relief may be for the types:

LM(A15), L(A15), S(B125) and T(S250) - diameter 2 to 6 mm;

TM(D400) and ST(E600) - "3" 8".

The surface area of the curved relief is made up of no less than 10% and no more than 70% of the surface area.

The configuration of the relief is set by the generator and may be determined by the regulation of the nominal voltage value, and by the production technology.

5.2.4 The design of the hatches requires the transfer of at least one recess or opening, designed to allow the lid to be opened.

5.2.5 Hatch covers, repair inserts and gratings of additional parts must fit freely into the corresponding housings. The gap between them along the perimeter should not exceed 3 mm on the side.

5.2.6 Manhole covers (except water supply ones) have holes with a diameter of at least 20 mm for collecting samples of gas contamination in wells.

5.2.7 Manhole covers, repair inserts and gratings must be firmly pressed against the proper supporting surfaces of their housings. The flatness tolerance of the supporting surfaces should not exceed 2 mm.

5.2.8 Hatches types T(S250), TM(D400), ST(E600), a similar repair insert and additional contacts of types DM(S250), DS(D400) with an elastic gasket between the cover and the body or the transmission mechanism I feel the supporting surfaces. The design, dimensions of the elastic gasket and method of fastening determine the manufacturing process. It is allowed to install several (instead of one part) elastic pads behind the washbasin to prevent the lid from collapsing. The hardness of the elastic gasket is not lower than 40 units. according to Shore.

5.2.9 The grooves in the main rails will be evenly distributed behind the surface of the clamping rail. The area of the grooves must be no less than 30% of the net area of the grate of the grate and may be indicated in the supporting documentation for the grate.

5.2.10 Grooves of types D(A15) and DB(B125) of different sizes:

width 8 to 18 mm; dovzhina is not limited;

width over 18 to 25 mm, width over 170 mm.

The dimensions of the grooves of the gratings of types DM (S250) and DS (D400) lie in line with the orientation of the later axes of the grooves of the transport arm in accordance with Table 3.

Table 3

|

Orientation |

Type |

Width, mm |

Dovzhina, mm |

|

View 0 to 45° and view 135 to 180° |

All types |

From 16 to 32 |

£ 170 |

|

View 45 to 135° |

DM(S250) |

View 16 to 42 |

No exchange |

|

DS(D400) |

» 20 » 42 |

5.2.11 The supporting surface of the body must be designed in such a way that the pressure on the supporting surface when the nominal tension is set does not exceed 7.5 MPa.

5.2.12 The design and dimensions of the locking structures of the hatches of the inspection wells, the hinged connections of the covers of the hatches and the gratings of the additional catches mean the operator of the weather conditions.

5.3 All parts, materials, purchased parts for the body, covers, repair inserts for hatches, the body and gratings of the gratings are made from gray chavun of a grade not lower than SCH20 according to GOST 1412. It is allowed to replace the brand with chavun, which will ensure є nominal vantage. In addition, it is allowed to manufacture hatch bodies of types LM(A15), L(A15) and door handles type D(A15) from polymeric materials and the frame is connected to concrete. Internal locking devices for hatches are made from steel grades no lower than St3 according to GOST 380 with anti-corrosion coatings.

5.4 Completeness

Hatches and door handlers are supplied both as a complete set and in additional parts.

5.5 Markuvannya

5.5.1 On the outer surface of the covers of hatches of all types and a variety of attachments there is a clear marking, including the words “hatch”, “attachment”, “repair insert” and the trademark of the manufacturing company. The designated engineering lines are installed along the axle line. On the inner surface of the lids of the hatches and a lot of additional agents, add a month and a period of cooking time. The dimensions of the marking signs indicate the vibrator.

5.5.2 Hatches and receptionists, in addition to accommodation, must be accompanied by a passport. Passport to take revenge:

the name of the pharmaceutical company and its trademark;

the mind is assigned to the virobu;

number of germs in a batch;

warranty term;

date of capture by technical control;

date of expansion.

5.6 Packaging

Packing of hatches and dockers is prepared in bags on pallets. Depending on the circumstances, other types of packaging are permitted to ensure the preservation of viruses during transportation and storage.

6 Rules for catching

6.1 The capture of hatches and accessory catches of all types, repair inserts (furthermore - virobs) should be carried out in batches. The party's commitment is to the old changeable vibration.

6.2 Viruses must undergo proper, periodic and routine testing.

6.3 During careful testing, the external appearance of the beans, the mechanical integrity of the lids and grids must be verified. The changes look like they have a leather hatch and a firebox; Conversion to mechanical value is provided by manhole covers and gratings for 3% of the batch, or at least two pieces.

6.4 If unsatisfactory results are obtained from testing for mechanical accuracy, during normal testing, re-check this indicator for the double number of viruses. The results of repeated verification are extended to the entire batch and remain residual.

6.5 During periodic testing, check the dimensions, the weight of the parts of the containers, the flatness of the covers of the hatches and gratings of the gratings and their bodies at least on three batches, so that Extensive testing has been carried out, at least once per river, and also after skin replacement of technological equipment .

6.6 Typical testing is carried out to verify the effectiveness and completeness of design changes or manufacturing technologies that may affect the technical characteristics of the product.

Testing is carried out on samples of products, the design of which has been changed on the stand for timely documents.

Seeing and obsyagi typical virobuvana means virobnik.

6.7 The owner has the right to carry out a control check of the conformity of all types of hatches, repair inserts and accessories to any possible standard, subject to the established procedure for the selection of signs and control methods.

7 Control methods

7.1 The dimensions of inspection well hatches, accessory and repair inserts are checked using universal and special tools, as well as templates.

7.2 Check the external appearance of hatches, access points and repair inserts.

7.3 The weight of hatch covers, casings and other parts must be no more than 0.5 kg.

7.4 The tolerance for the flatness of the hatch cover or the level of the additional catcher is indicated on the turning plate behind an additional set of feeler gauges.

7.5 Testing for mechanical strength is carried out on a press, which ensures the necessary strength. Pres may be in possession of a steel punch. The punch is aligned.

To test the hatch or the dowel receptacle, install it on the press bed, their supporting surfaces must be pressed against the frame along the entire supporting surface.

The pressure on the hatch cover or the grate of the catcher must be applied exactly in the middle through the gasket of the gasket of at least 3 mm. The pressure must be gradually increased to 5 kN/s until the nominal pressure is reached. Viprobovuvalne navantazhennya vitrimuyut stretching schonaymenshe 30 z.

The hatch or the inspector is respected in such a way that it has been tested, so that no damage (cracks, splinters) will be revealed.

8 Transportation and saving

8.1 Hatches and accessory devices can be transported by any type of transport in accordance with the transportation rules that apply to this type of transport. When transported by road, hatches may not be packaged. The attraction in this case may be equal and uneasy to move the vantage and the other way around.

8.2 All types of transport labeling comply with GOST 14192.

8.3 Cleaning of hatches - according to group Zh 1 GOST 15150.

9 Producer guarantees

9.1 Virobnik guarantees the conformity of hatches, fittings and repair inserts to the required standard for safe transportation and conservation.

300 £ PZ £ 1000

200 £ PZ £ 300

200 £ PZ £ 300

Keywords: hatches, inspection wells, catchers, drainage wells, communications engineers, thermal lines, water supply, sewerage

Chavunny hatch DERZHSTANDARD 3634 99 applications for installation on inspection wells of underground communications. The variety of types is related to the level of use, resistance to wear and safety techniques. The preparation of dry viruses and materials is regulated by established international standards.

Types of dry hatches and their meanings

Access to the inspection of underground communications, such as drainage, cable, and pipeline systems, is provided by the sewer hatch of the inspection well.

The main purpose of the covers is to ensure the safety of pedestrians and cars, as well as to protect against damage and damage to the boundaries located under the ground.

The standard for chavunny covers for inspection wells is divided on the basis of light-based materials for marking, design, testing and control of the viability of germs. Hatches are prepared in accordance with GOST 3634 99 “Hatches for inspection wells and additional intakes for storm drainage wells.”

It is important to distinguish between different types of hatches when installing vanity systems. The smell is due not only to the ease of installation and operation, but also to the aesthetic surface design, saving technical parameters, regardless of the minds of the victor.

Heavy duty structures with a diameter of 550 mm, a weight of 155 kg, a nominal tension of 600 kN, are installed in docks and airfields.

Heavy duty structures with a diameter of 550 mm, a weight of 155 kg, a nominal tension of 600 kN, are installed in docks and airfields.

Heavy main hatches with a weight of approximately 140 kg are mounted on main lines, with a force of up to 400 kN. On public roads with intense traction, a vehicle with a mass of 120 kg and a nominal tension of 250 kN is installed.

Medium virobes, which can vibrate pressure up to 125 kN, are installed in residential areas and roads bordering transport zones. Installation of lightweight sewer manholes, weighing 65 kg, on sidewalks, pedestrian areas, and lawns.

Hatches for wells are manufactured in accordance with the established standard for hardened chairs. The injections are not to blame for defects that affect the quality of the product.

The design has at least one opening, which ensures the possibility of opening the lid. It must immediately land firmly on the supporting surface and firmly enter the body.

To characterize the chavun hatches of round inspection wells, there are 2 main parameters for them - the external and internal diameter of the opening.

All dimensional parameters are specified in GOST 363499, but in practice you can find the covers of manholes with a diameter of 380-810 mm. The size of the full opening should be 450–550 mm.

The cover of the dry design can be square in shape. The minimum side depth can be 300 mm and increased by 50 mm with the skin edge. The optimal dimensions of such a structure are 800 mm.

Technical characteristics

Chavunny hatches are usually equipped with an elastic gasket between the upper and lower parts of the structure. The material from which hysterical beetles are prepared for inspection wells may comply with the national standard.

Chavunny hatches are usually equipped with an elastic gasket between the upper and lower parts of the structure. The material from which hysterical beetles are prepared for inspection wells may comply with the national standard.

Hatch covers and bodies are made from gray chavun grade SCH20. In times of need, it is allowed to replace the material with a different brand to ensure maximum performance.

Apply the marking to the outer part of the plant hatch structure, and the date of manufacture to the inner part. Each virus contains a passport, which contains information about the virus, a guarantee term of operation, and the date of acceptance by the technical control department.

The leather lot is subject to testing for its value and testing until the infusion of mechanical requirements.

The operating capacity of sea hatches should be no less than 80 tons, and the volume that is visible is up to 90 tons. The stench is persistent up to temperature changes. One thing about chavun structures is their high quality.

The operating capacity of sea hatches should be no less than 80 tons, and the volume that is visible is up to 90 tons. The stench is persistent up to temperature changes. One thing about chavun structures is their high quality.

The lining of the technological well is associated with the need for continuous maintenance and continuous repair of various types of highways. Therefore, such structures are reliable and will provide access to underground communications.

Installation and operation

Tightly closing the hatch covers does not guarantee complete safety and protection against the entry of various objects into the opening. Head meta, for which, when preparing vikoryst, an important material is used, avoiding fallout.

Tightly closing the hatch covers does not guarantee complete safety and protection against the entry of various objects into the opening. Head meta, for which, when preparing vikoryst, an important material is used, avoiding fallout.

Chavunna krishka is important, so for her to achieve this goal, it is necessary to apply singing force. Chavun is resistant to the influx of atmospheric moisture, corrosion, mitigation, and does not crack under the infusion of moisture.

Access to the inspection room, which includes the distribution and locking equipment assemblies, as well as control mechanisms and control systems, is ensured by the hatch cover.

Open the wells and make sure to close them tightly so that they cannot be opened by sudden one-sided access or passages.

If the installation of the hatch needs to be done on the accessory area, then the main considerations must be made when installing the supporting part of the structure. The support ring has technological openings, which are necessary for a clear armored structure.

The cover of the sewer well must be high above the surface of its location on the lawn. When installing on the other part, it is necessary to ensure minimal deflection in the area where the cover will be installed to ensure water drainage.

The ease of installation is closely related to the following rules of operation. The kryshka krynitsa must be opened with special care, especially since it is cut off from the chavun. Great force may cause injury.

The open container must be ventilated, and all work is allowed to be carried out unless there is evidence of individual protection.

Since these structures are the most extensive, then, obviously, they are characterized by a large number of advantages, among them:

- The stench of the building exudes grandeur.

- The great importance of the devices means that the lid cannot be opened suddenly and will not open during transport transfer.

- They are offered at a democratic price.

- They do not recognize external influxes.

- High frost resistance.

- A trivial term of exploitation.

- They may be of different sizes and different sizes, so they are subject to different requirements. Easy installation is important. They can easily be used in park areas, squares, on sidewalks, on country plots to close septic tanks and drainage wells. Heavy vehicles, in their own way, are installed on Moscow highways, autobahns, and moderate and intense traffic. They can be used at industrial sites, highways, heat and gas lines.

- The ribbed surface of the lid adds greater value to the structure.

If there are not enough people, then we are in the first place. It prevents the protection of wells, and at the same time makes it possible to move devices and lift them. Also, such settings are advantageous for villains, since they can be created from chavun.