Duplex stainless steels. Analogs of Russian and foreign steels Marked for EN

Duplex stainless steels are becoming increasingly wider. They are produced by all major stainless steel manufacturers - and for the following reasons:

- High value, which allows the transmission of viruses

- High corrosion resistance, especially to corrosion cracking

Every 2-3 years are held dedicated to duplex steels of the conference, where dozens of in-depth technical articles are presented. Let's actively push this type of steel over the market. New brands of these steels are constantly appearing.

Regardless of all this, the share of duplex steels on the light market is, according to the most optimistic estimates, from 1 to 3%. Meta stats - in simple words explain the peculiarities of this type of steel. Both advantages and shortcomings will be described viruses made of duplex stainless steel.

News about duplex stainless steels

The idea of creating duplex stainless steels began in the 1920s, and the first smelting began in the 1930s in Avesta, Sweden. Due to the increased growth of the vicor of duplex steels, the remaining 30 years are lost. It is explained that it is important to improve the technology of steel production, especially the processes of regulation of nitrogen in steel.

Traditional austenitic steels, such as AISI 304 (analogues of DIN 1.4301 and 08Х18Н10), and ferritic steels, such as AISI 430 (analogues of DIN 1.4016 and 12Х17), are easy to prepare and easy to machine. As their names suggest, the smell consists primarily of one phase: austenite and ferrite. Although these types cover a wide range of stagnation, these types cover their technical shortcomings:

In austenitic ones, there is a low density (the average linearity limit is 0.2% at the mill after austenization of 200 MPa), low resistance to corrosion cracking

Feritic ones have a low value (a little more, austenitic ones have a lower value: the average between linearity of 0.2% becomes 250 MPa), poor boilability during high temperatures, low-temperature crispiness

In addition, high nickel content in austenitic steels leads to their increase in price, which is undesirable for most end users.

The main idea of duplex steels lies in the selection of such a chemical composition, which creates approximately the same strength of ferite and austenite. Such a phase warehouse will ensure offensive advantages:

1) High value - the range of intellectual inter-linearity is 0.2% for current duplex steel grades, becoming 400-450 MPa. This allows you to change the composition of the elements, and therefore their mass.

This advantage is especially important in the following areas:

- Judge under pressure and tanks

- Building structures, for example, bridges

2) The quality of the great products is good - not as simple as the austenite ones, but much better than the ferrite ones.

3) Good impact toughness - much better than that of ferritic steels, especially at low temperatures: up to minus 50 degrees Celsius, in some cases - up to minus 80 degrees Celsius.

4) Support to corrosion cracking (SCC) – traditional austenitic steels are especially developed to this type of corrosion. This advantage is especially important when preparing such structures as:

- Hot water tanks

- Brewery tanks

- Salary installations

- Pool frames

What is the equivalent of austenite/ferite?

To understand how duplex steel comes out, you can first equalize the stock of two well-known steels: austenitic - AISI 304 (analogues of DIN 1.4301 and 08Х18Н10) and ferritic - AISI 430 (analogues of DIN 1.4016 and 12Х17).

|

Structure |

Brand |

Poznachenya EN |

|||||||||

|

Feritna |

16,0-18,0 |

||||||||||

|

Austenitic |

17,5-19,5 |

8,0-10,5 |

The main elements of stainless steels can be divided into ferritizing and austenizing ones. The skin from the elements combines the creation of the same structure and other structures.

Ferritizing elements - Cr (chromium), Si (silicon), Mo (molybdenum), W (tungsten), Ti (titanium), Nb (niobium)

Austenising elements – ce C (carbon), Ni (nickel), Mn (manganese), N (nitrogen), Cu (copper)

In AISI 430 steel, ferritizing elements are important, which is why it has a ferritic structure. AISI 304 steel has an austenitic structure, which is important for the ratio of approximately 8% nickel. To remove the duplex structure from the skin phase, approximately 50% is the required balance of austenitizing and ferritizing elements. This is the reason why, instead of nickel in duplex steels, the metal is lower than in austenite steels.

Below is a typical warehouse of duplex stainless steel:

|

Brand |

EN/UNS number |

Zrazkovyj zmіst |

|||||||

|

LDX 2101 |

1.4162/

|

Malolegovana |

|||||||

|

1.4062/ S32202 |

Malolegovana |

||||||||

|

1.4482/

|

Malolegovana |

||||||||

|

1.4362/

|

Malolegovana |

||||||||

|

1.4462/

|

Standard |

||||||||

|

1.4410/

|

Super |

||||||||

|

Zeron 100 |

1.4501/

|

Super |

|||||||

|

Ferrinox255/

|

1.4507/

|

Super |

|||||||

In some of the recently released brands, for a significant reduction, instead of nickel, vicor is added to nitrogen and manganese. This has a positive impact on price stability.

The technology for producing duplex steels is still developing. That's why the leather dealer pushes his brand. To be honest, there are a lot of brands of duplex steel. But, regardless of everything, we can avoid such a situation until “overcomes” appear in the middle.

Corrosion resistance of duplex steels

Due to the diversity of duplex steels, their corrosion resistance should be achieved simultaneously with austenitic and ferritic grades of steel. The same measure of corrosion resistance has not yet faded. However, for the classification of steel grades, it is necessary to calculate the numerical equivalent of resistance to pitting corrosion (PREN).

PREN = % Cr + 3.3 x % Mo + 16 x % N

Below is a table of the corrosion resistance of duplex steels compared to austenitic and ferritic grades.

|

Brand |

EN/UNS number |

Orient PREN |

|

|

1.4016/

|

Feritna |

||

|

1.4301/

|

Austenitic |

||

|

1.4509/

|

Feritna |

||

|

1.4482/

|

Duplex |

||

|

1.4401/

|

Austenitic |

||

|

1.4521/

|

Feritna |

||

|

316L 2.5Mo |

Austenitic |

||

|

2101 LDX |

1.4162/

|

Duplex |

|

|

1.4362/

|

Duplex |

||

|

1.4062/ S32202 |

Duplex |

||

|

1.4539/

|

Austenitic |

||

|

1.4462/

|

Duplex |

||

|

Zeron 100 |

1.4501/

|

Duplex |

|

|

Ferrinox 255/ |

1.4507/

|

Duplex |

|

|

1.4410/

|

Duplex |

||

|

1.4547/

|

Austenitic |

It should be noted that this table can only serve as a guide to the selection of material. First of all, it is necessary to consider how suitable the steel is for use in a particular corrosive medium.

Stress Corrosion Cracking (SCC)

SCC is one of the types of corrosion that is caused by a combination of external factors:

- Tensile voltage

- Corrosive middle

- Temperatures up to 50 degrees Celsius are high, but in some cold weather, such as swimming pools, they can be found at temperatures around 25 degrees Celsius.

Unfortunately, the primary austenitic steels, such as AISI 304 (analogues of DIN 1.4301 and 08Х18Н10) and AISI 316 (analogue of 10Х17Н13М2) are the most resistant to SCC. The advanced materials may have a much higher resistance to CR:

- Feritic stainless steels

- Duplex stainless steels

- Austenitic stainless steels with high nickel content

Opera SCC allows duplex steels to be processed in a variety of processes that take place at high temperatures, such as:

- In water heaters

- At the brewing tanks

- In desalination plants

The frames of the pools are made of stainless steel and are characterized by their strength up to SCC. Their manufactured primary austenitic stainless steels, such as AISI 304 (analogue 08Х18Н10) and AISI 316 (analogue 10Х17Н13М2) are shielded. For this purpose, austenitic steels with a high nickel content, such as grades with 6% Mo, are most suitable. However, in some cases, duplex steels such as AISI 2205 (DIN 1.4462) and super duplex steels can be considered as an alternative.

Officials who can overcome the wider range of duplex steels

By adding high value, a wide range of corrosion resistance values, medium weldability, the idea holds great potential for increasing the share of duplex stainless steels on the market . However, it is necessary to understand that duplex stainless steels have shortcomings and why they, which matter to everyone, will lose the status of “cheap metals”.

Such an advantage as the high value of Mittevo is transformed into not enough, How to get to the technological level of processing the material with a vice and mechanical processing only on the right. High value also means lower, lower than austenitic steels, resistance to plastic deformation. Therefore, duplex fibers have become practically unsuitable for the production of viruses, as they require high plasticity. And if the material is subject to plastic deformation at a reasonable level, more force is required to give the required shape to the material, such as, for example, with bent pipes. However, there is one fault with the rules: brand LDX 2101 (EN 1.4162) from Outokumpu.

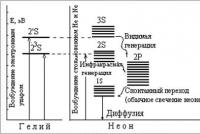

The melting process of duplex stainless steels is much more complex than that of austenitic and ferritic steels. If the technology of fermentation, heat treatment, austenite and ferite in duplex steels is damaged, low-grade phases can be created. The two most significant phases of the image are shown below the diagram.

To make it larger, press it onto the image.

Resentment phases lead to the appearance of cracking, then loss of shock value.

Illumination of the sigma phase (over 1000 º C) is most often observed when there is insufficient cooling liquid during preparation or boiling. The more alloying elements in steel, the greater the consistency of the sigma phase. Therefore, the most resistant to this problem are super duplex steels.

The 475-degree crispness appears as a result of the establishment of a phase called α′ (alpha prime). Although the most dangerous temperature is 475 degrees Celsius, it can be cured at lower temperatures, even up to 300º C. This affects the maximum operating temperature of duplex steels. This exchange is even more pronounced around large areas of stagnation.

On the other hand, there is a requirement for the minimum operating temperature of duplex steels, which are lower than austenite steels. In contrast to austenitic steels, duplex steels undergo a tendent transition during impact testing. The standard temperature for testing steels that are vicorized in structures for offshore production of oil and gas is minus 46 º C. Therefore, duplex steels are not vicorized at temperatures below minus 80 degrees Celsius.

A quick look at the power of duplex steels

- Rozrakhunkova value in both materials, lower in austenitic and ferritic stainless steels

- Wide range of corrosion resistance values, which allows you to select a brand for a specific application

- Good shock value up to minus 80 C, which prevents stagnation in cryogenic media.

- Vinyatkov resistance to corrosion cracking

- Good cooking properties of great cuts

- Greater foldability during mechanical processing and stamping of the bottom of austenitic steels

- The maximum operating temperature is 300 degrees.

Material taken from the website of the British Stainless Steel Association www.bssa.org.uk

Analogues of Russian and foreign steels

Lower edges and metal standards in them:

- Australia - AS (Australian Standard)

- Austria - ONORM

- Belgium - NBN

- Bulgaria - BDS

- Ugorshchina - MSZ

- Great Britain – B.S. (British Standard)

- Nіmechchina - DIN (Deutsche Normen), W.N.

- European Union - EN (European Norm)

- Italy - UNI (Italian National Standards)

- Spain - UNE (Espaniol National Standards)

- Canada - CSA (Canadian Standards Association)

- China - GB

- Norway - NS (Standards Norway)

- Poland – PN (Poland Norm)

- Romania - STAS

- Russia - GOST (National standard), THAT (Technical minds)

- USA - AISI (American Iron and Steel Institute),ACI (American Concrete Institute),ANSI (American National Standards Institute), A.M.S. (American Mathematical Society: Mathematics Research and Scholarship),API (American Petroleum Institute), A.S.M.E. (American Society of Mechanical Engineers),ASTM (American Society of Testing and Materials),AWS (American Welding Society),SAE (Society of Automotive Engineers), UNS

- Finland - SFS (Finnish Standards Association)

- France - AFNOR NF (association francaise de normalization)

- Czech Republic - CSN (Czech State Norm)

- Sweden - SS (Swedish Standard)

- Switzerland – SNV (Schweizerische Normen-Vereinigung)

- Yugoslavia – JUS

- Japan - JIS (Japanese Industrial Standard)

- International standard - ISO (International Organization for Standardization)

The United States has a number of systems for assigning metals and alloys associated with various standardization organizations. The most prominent organizations are:

- AISI - American Institute of Chavunu and Steel

- ACI - American Litt Institute

- ANSI – American National Standards Institute

- AMS - Aerospace Materials Specification

- ASME - American Fellowship of Mechanical Engineers

- ASTM - American Partnership for Material Testing

- AWS - American Partnership of Zvaryuvalniki

- SAE - Partnership of Engineers - Motorists

The most popular systems of value have become lower, which are being used in the USA.

AISI system:

Carbon steel and alloy steel:

In the system, AISI values for carbon and alloy steels are usually indicated by several additional numbers. The first two digits indicate the steel group number, and the remaining two digits indicate the average amount of carbon in steel, multiplied by 100. So steel 1045

reach the group 10XX acid structural steels (non-sulfinated with Mn content less than 1%) and carbon content of approximately 0.45%.

Steel 4032

є alloy (group 40XX), from average instead of C - 0.32% and Mo - 0.2 or 0.25% (real instead of C in steel 4032

- 0.30 – 0.35%, Mo – 0.2 – 0.3%).

Steel 8625

also alloyed (group 86ХХ) from the middle: C - 0.25% (real values 0.23 - 0.28%), Ni - 0.55% (0.40 - 0.70%), Cr - 0.50% (0.4 - 0.6%), Mo - 0.20% (0.15 - 0.25%) .

In addition to several numbers, the names of steels may have the same values. When the letters are Bі L, which means that the steel is alloyed with either boron (0.0005 - 0.03%) or lead (0.15 - 0.35%), placed between the other and the third digit of the same designation, for example: 51B60 or else 15L48.

Literi Mі E put the name of the steel first, which means that the steel is intended for the production of unconventional rolled products (type M) or melted in an electric furnace (litera E). For example, the name can be used as a letter H, Which means that the characteristic sign of it is frying.

Stainless steels:

The AISI designation of standard stainless steels includes three numbers followed by one, two or more numbers. The first number indicates the steel class. So the designations of austenitic stainless steels begin with numbers 2XXі 3XX, at that hour, as ferrites and martensists began to be identified in the class 4XX. In this case, the remaining two numbers in the category of carbon and alloy steels are in no way related to the chemical composition, but simply indicate the serial number of the steel in the group.

Designation for carbon steels:

10ХХ - Non-resulfinated steels, Mn: less than 1%

11ХХ - Resulfinated steels

12ХХ - Rephosphorized and resulfinated steels

15ХХ - Non-resulfinated steels, Mn: more than 1%

Designations for alloyed steels:

13ХХ - Mn: 1.75%

40ХХ - Mo: 0.2, 0.25% or Mo: 0.25% and S: 0.042%

41ХХ - Cr: 0.5, 0.8 or 0.95% and Mo: 0.12, 0.20 or 0.30%

43ХХ - Ni: 1.83%, Cr: 0.50 - 0.80%, Mo: 0.25%

46ХХ - Ni: 0.85 or 1.83% and Mo: 0.2 or 0.25%

47ХХ - Ni: 1.05%, Cr: 0.45% and Mo: 0.2 or 0.35%

48ХХ - Ni: 3.5% and Mo: 0.25%

51ХХ - Cr: 0.8, 0.88, 0.93, 0.95 or 1.0%

51ХХХ - Cr: 1.03%

52ХХХ - Cr: 1.45%

61ХХ - Cr: 0.6 or 0.95% and V: 0.13% min or 0.15% min

86ХХ - Ni: 0.55%, Cr: 0.50% and Mo: 0.20%

87ХХ - Ni: 0.55%, Cr: 0.50% and Mo: 0.25%

88XX - Ni: 0.55%, Cr: 0.50% and Mo: 0.35%

92XX - Si: 2.0% or Si: 1.40% and Cr: 0.70%

50BXX - Cr: 0.28 or 0.50%

51BXX - Cr: 0.80%

81BXX - Ni: 0.30%, Cr: 0.45% and Mo: 0.12%

94BXX - Ni: 0.45%, Cr: 0.40% and Mo: 0.12%

Additional letters and numbers that follow the numbers that are used for the designation of stainless steels according to AISI mean:

xxxL - Low instead of carbon< 0.03%

xxxS - Normal instead of carbon< 0.08%

xxxN - Added nitrogen

xxxLN - Low carbon content< 0.03% + добавлен азот

xxxF - Advances instead of sirka and phosphorus

xxxSe - Dodaniy selenium

xxxB - Dodaniy flint

xxxH - Extend the interval instead of the carbon

xxxCu - Added copper

Apply:

Steel 304

reach the austenite class, instead of carbon in it< 0.08%. В то же время в стали 304 L all sorts of things< 0.03%, а в стали 304H The carbon is indicated in the interval 0.04 – 0.10%. The steel indicated may also be alloyed with nitrogen (then this will be called 304 N) or mіddyu ( 304 Cu).

In steel 410

, which is related to the martensitic-feritic class, instead of carbon<< 0.15%, а в стали 410 S- vugletsyu< 0.08%. В стали 430F under change in steel 430

displacements instead of sulfur and phosphorus, and into steel 430F Se additional selenium.

ASTM marking system:

The classification of steels in the ASTM system includes:

- letter A What does it mean that we are talking about black metal;

- serial number of the ASTM regulatory document (standard);

- Vlasne designated steel grade.

According to ASTM standards, the American system of designation of physical quantities is adopted. In the same way, since the standard has a metric system of numbers, a letter is placed after the number M. ASTM standards, therefore, indicate that the steel is a chemical warehouse, and its re-processing is possible before metal products. For the designation of steel grades and their chemical grades, the ASTM marking system can be used (for which grade the chemical stock of steels and their grades are assigned directly to the standard), as well as other marking systems, for example AISI treasure - for rods, darts, preparations and or ACI - for forgings made of stainless steel.

Apply:

A 516 / A 516M - 90 Grade 70 Here A means that we are talking about black metal; 516

- this is the serial number according to the ASTM standard ( 516M- this is the same standard, but in the metric system it is a value); 90

- rik to the standard; Grade 70- Steel grade. In this case, the ASTM steel designation system is reviewed, here 70

means the minimum value of steel during tensile testing (ksi, which is approximately 485 MPa).

A 276 Type 304 L. This standard is based on the designation of steel grades in the AISI system - 304 L.

A 351 Grade CF8M. The ACI value system is discussed here: first letter C means that the steel reaches the corrosion-resistant group, 8

- Means the average amount of carbon in it (0.08%), M- means that molybdenum is added to steel.

A 335 / A 335M grade P22; A 213 / A 213M grade T22; A 336 / A 336M class F22. These stocks are subjected to ASTM steel grades. First letters mean that the steel is intended for making pipes ( P or else T) or forgings ( F).

A 269 grade TP304. Here the value system is combined. Literi TP It means that steel is intended for making pipes, 304

- this is designated by the AISI system.

UNS universal system:

UNS is a universal system for identifying metals and alloys. It was created in 1975 as a way to unify various systems used in the United States. Apparently up to UNS, the designations of steels are made up of letters, which means a group of steels and five digits.

The UNS system has the simplest classification of AISI steels. For structural and alloy steels, which must be included in the group G, the first digits are named in the AISI system, the last digit replaces the numbers that appear in the AISI designations. So to the letters Bі L What does it mean that the steel is alloyed with boron or lead, as indicated by the numbers 1

і 4

, and the letters E What does it mean that the steel was smelted in an electric furnace - number 6

.

The names of stainless AISI steels begin with the letter S and include steel designations according to AISI (the first three digits) and two additional digits that correspond to additional letters in the designation for AISI.

Designation of steels in the UNS system:

Dxxxxx - Steel with reinforced mechanical powers

Gxxxxx - Carbon steel and alloy steel AISI (except for tooling)

Hxxxxx - The same, but for steels that are fried.

Jxxxxx - Livarni steel

Kxxxxx - Steels not included in the AISI system

Sxxxxx - Heat and corrosion resistant stainless steels

Txxxxx - Tool steels

Wxxxxx - Cooking materials

Additional letters and numbers that follow the numbers that are used for assigning stainless steels to UNS mean:

xxx01 - Low carbon content< 0.03%

xxx08 - Normal instead of carbon< 0.08%

xxx09 - Extending the interval instead of a carbon

xxx15 - Dodaniy flint

xxx20 - Advances instead of syrup and phosphorus

xxx23 - Dodaniy selenium

xxx30 - Added copper

xxx51 - Adding nitrogen

xxx53 - Low carbon content< 0.03% + добавлен азот

Apply:

Vuglets steel 1045

May be assigned to the system UNS G 10450, and alloyed steel 4032

- G 40320.

Steel 51B60, doped with boron, called in the system UNS G 51601, and steel 15L48, alloyed with lead, - G 15484.

Stainless steels are designated: 304

- S 30400, 304 L - S 30401, 304H - S 30409, A 304 Cu - S 30430.

|

Steel grade |

Analogues of US standards |

||

|

Regions SND GOST |

Euronormie |

||

|

R0 M2 SF10-MP |

|||

|

R2 M10 K8-MP |

|||

|

R6 M5 K5-MP |

|||

|

R6 M5 F3-MP |

|||

|

R6 M5 F4-MP |

|||

|

R6 M5 F3 K8-MP |

|||

|

R10 M4 F3 K10-MP |

|||

|

R6 M5 F3 K9-MP |

|||

|

R12 M6 F5-MP |

|||

|

R12 F4 K5-MP |

|||

|

R12 F5 K5-MP |

|||

Structural steel:

|

Steel grade |

Analogues of US standards |

||

|

Regions SND GOST |

Euronormie |

||

Basic range of stainless steel grades:

|

SND (GOST) |

Euronormie (EN) |

Nіmechchina (DIN) |

USA (AISI) |

|

03 X17 N13 M2 |

X2 CrNiMo 17-12-2 |

||

|

03 X17 N14 M3 |

X2 CrNiMo 18-4-3 |

||

|

03 X18 N10 T-U |

|||

|

06 ХН28 MDT |

X3 NiCrCuMoTi 27-23 |

||

|

08 X17 N13 M2 |

X5CrNiMo 17-13-3 |

||

|

08 X17 N13 M2 T |

Х6 CrNiMoTi 17-12-2 |

||

|

Х6 CrNiTi 18-10 |

|||

|

20 Х25 Н20 С2 |

X56 CrNiSi 25-20 |

||

|

03 X19 N13 M3 |

|||

|

02 X18 M2 BT |

|||

|

02 X28 N30 MDB |

X1 NiCrMoCu 31-27-4 |

||

|

03 X17 N13 AM3 |

X2 CrNiMoN 17-13-3 |

||

|

03 X22 N5 AM2 |

X2 CrNiMoN 22-5-3 |

||

|

03 X24 N13 G2 S |

|||

|

08 X16 N13 M2 B |

X1 CrNiMoNb 17-12-2 |

||

|

08 X18 N14 M2 B |

1.4583 X10 CrNiMoNb |

X10 CrNiMoNb 18-12 |

|

|

X8 СrNiAlTi 20-20 |

|||

|

X3 CrnImOn 27-5-2 |

|||

|

Х6 CrNiMoNb 17-12-2 |

|||

|

X12 CrMnNiN 18-9-5 |

|||

Bearing steel:

|

Steel grade |

Analogues of US standards |

||

|

Regions SND GOST |

Euronormie |

||

Spring steel:

|

Steel grade |

Analogues of US standards |

||

|

Regions SND GOST |

Euronormie |

||

Heat-resistant steel:

|

Steel grade |

Analogues of US standards |

||

|

Regions SND GOST |

Euronormie |

||

Compliance between domestic and foreign standards for steel and pipes

Standards for steel

|

Nіmechchina |

European Union |

ISO-standard |

England |

France |

Italy |

Russia |

|

|

DIN 17200 |

heat-treated steel |

NFA 35-552 |

UNI 7845 |

GOST 4543-71 |

|||

|

case-hardened steel |

GOST 4543-71 |

||||||

|

hot rolled steel for annealed springs |

|||||||

|

spring wire and steel tape of rustless steel |

|||||||

|

ball bearing/trolley steel |

|||||||

|

Temperature and high temperature material grade for screws and nuts |

GOST 5632-72 |

||||||

|

forging and rolled or forged steel bar of temperature, weldable steel |

ISO 2604/1 |

||||||

|

steel tools including high-quality steel |

GOST 1435 |

||||||

|

DIN 17440 |

BS 970/1 |

UNI 6900 |

GOST 5632-72 |

||||

|

rustless steel for medical equipment |

|||||||

|

rustless steel for surgical implant |

|||||||

|

valve material grade |

GOST 5632-72 |

||||||

|

non-magnetic steel |

|||||||

|

SEW 470 |

heat-resistant steel |

BS 1554-81 |

UNI 6900 |

GOST 5632-72 |

|||

|

constructional steel |

Universal stainless steel AISI 304 and AISI 304L.

The AISI304 grade is the most universal and the most widely used of all stainless steel grades. Its chemical storage, mechanical strength, welding and resistance to corrosion/oxidation will ensure the greatest choice in a large variety of products at a remarkably low price. This steel also has miraculous low-temperature power.Galuz zastosuvannya

Corrosion-resistant, austenitic, unstabilized steel that can be welded. This is especially true for the preparation of chemical reactors, including high pressure vessels. It is suitable for mediums of an oxidizing nature, for strong inorganic acids only at low concentrations and at low temperatures. It is suitable for weak organic acids at medium temperatures and in contact with surfaces. It is used in production of spare parts and equipment in food, chemical and fermentation industries (at temperatures up to 300 C). Possibly, AISI 304 steel is used for products that require additional hygienic cleanliness of the product - food industry and elements of refrigeration and freezing devices (salt mixture).

The steel has excellent polishing properties and particularly good ductility and resistance to deep stretching. It is suitable for carrying out water, steam, and grub acids. This steel is most often used in the dairy industry, brewing industry, cosmetics industry, as well as in the chemical and pharmaceutical industries.

The development of the grub industry has led to the fact that materials 304 and 316Ti are now almost completely replaced by materials 304L and 316L.

Type of European steel standards

304 1.4301 X2CrNi18-10304L 1.4306 X2CrNi19-11

304L 1.4307 X2CrNiTi18-10

316L 1.4404 X2CrNiMo17-12-2

316L 1.4435 X2CrNiMo18-14-3

316L 1.4571 X6CrNiMoTi17-12-2

Steel A2 (AISI 304 = 1.4301 = 08Х18Н10)– non-toxic, non-magnetic, non-hardened, corrosion resistant steel. It is easy to cook and does not become tender. You can exhibit magnetic power as a result of mechanical processing (washers and screws). This is the widest group of stainless steels. The closest analogues are 08Х18Н10 GOST 5632, AISI 304 and AISI 304L (with reduced carbon instead).

Stainless steel for grub industry

There are a number of grades of stainless steel that are used as structural materials for food production. Their choice is to keep away from the corrosive properties of the product that is being produced, or the chemicals that come into contact with this material. The most widely used steel grades are austenitic stainless steels (AISI 304, AISI 316 and AISI 316L as classified by the American International Standards Institute, AISI) with outstanding mechanical and technological properties. These things loom with an added appearance.AISI 304 (beyond DIN no. 1.4301) is the cheapest steel that is widely used in the food industry and in the industry due to its high corrosion resistance in various media, as well as ease of forming and welding Yuvannya.

AISI 316 (per DIN no. 1.4401) characterized by the addition of molybdenum (2-3 g/100 g), which increases corrosion resistance.

AISI 316L (per DIN no. 1.4404)- the price of low-carbon steel (maximum carbon content is 0.03 g/100 g) is equal to AISI 316, which has a maximum carbon content of 0.08 g/100 g. This brand is often recommended for preparation of pipelines and tanks.

All stainless steels in the presence of chlorine are susceptible to corrosion - point, crack or permanent, which is clearly localized and the stage of which is stored due to the infusion of the chemical medium, pH value, temperature, steel production methods, strength during stretching, acid concentration and surface finishing strength.

For use in aggressive environments, other materials such as Incoloy 825 (a heat-resistant nickel-chromium alloy), titanium steel and steel smelted through the duplex process are used, but they are much more expensive.

Steel is called an alloy of salinity and carbon.

Depends on percentage instead of carbon" Z"In such an alloy, steel has different strengths and characteristics. By adding various chemical elements to the alloy during melting (called “light elements”), it is possible to extract steels with different strengths. Steels with similar characteristics They were picked in the group.

In order for a steel to be called stainless, the amount of chromium in such steel is greater than 10.5% and the content of carbon is low (no more than 1.2%). The presence of chromium gives the steel its corrosion resistance - hence the name “stainless”. In addition to chromium, as a “binding stainless component,” stainless steel may also contain alloying elements: nickel (Ni), molybdenum (Mo), Titanium (Ti), Niobium (Nb), Sulfur (S), Phosphorus ( P) those other elements, the combination of which means the power of steel.

Main grades of stainless steels for fastening

Historically, it has developed so that the development and smelting of new stainless steels and alloys is closely linked with advanced technological fields: flight production and rocket production. The leading powers of the world in these galuzes were the machinery of the SRSR and, for a troubling hour, they were at the station of the “Cold War” and the skins of their path. Europe's technological leader in the 20th century was Germany. From them, they divided their classification of stainless steels: the USA has a system AISI, in Nіmechchyn - DIN, in the USSR - GOST.

There has been no talk about cooperation between these three leaders for a long time - there are a large number of current standards on stainless steel, and they are even more difficult, and sometimes they interact with each other noticeability.

The USA and Germany seem to be simpler: after all, between these countries for a decade there has been mutual trade in technical features and technologies, which inevitably led to mutual accession, and in the development of standards for stainless steel steel also Most importantly, the countries of the former Soviet Socialist Republic, where standards developed in isolation against the world, and today there are simply all kinds of analogues for many grades of imported stainless steels - or for example: all day long imported analogues of Radian stainless steels and many steels.

This whole situation is extremely disturbed and complicates the development of the ham machine industry, as it is called “chewing on knees.”

As a result, we have the following light standards for stainless steel:

- DIN- Deutsche Industrie Norm

- EN- Euronorm standard EN 10027

- DIN EN- German version of the European standard

- ASTM- American Society for Testing and Materials

- AISI- American Iron and Steel Institute

- AFNOR- Association Francaise de Normalization

- GOST- State standard

Massive and serial manufacturers of stainless steel fastenings are daily in Ukraine, so we are all concerned about the need to adhere to foreign classification and marking of stainless steels and fastening.

In the future, Russian standards for stainless steel fastening will be confirmed, which will take over the terminology and marking from European standards (for example, DSTU ISO 3506-2-2009). In Ukraine, having seen everything, the daily changes and innovations are not transferred to the nearest future...

And yet, stainless steels, which are most suitable for fastening, have close analogues in various classification systems - the main ones are shown in the following table of types of grades of stainless steels for fastening :

| Stainless steel standards | Volume of volatile elements, % | |||||||||

| * | DIN | AISI | GOST | C | Mn | Si | Cr | Ni | Mo | Ti |

| Z 1 | 1.4021 | 420 | 20Х13 | 0,20 | 1,5 | 1,0 | 12-14 | |||

| F1 | 1.4016 | 430 | 12Х17 | 0,08 | 1,0 | 1,0 | 16-18 | |||

| A1 | 1.4305 | 303 | 12Х18Н10Э | 0,12 | 6,5 | 1,0 | 16-19 | 5-10 | 0,7 | |

| A2 | 1.4301 | 304 | 12Х18Н10 | 0,07 | 2,0 | 0,75 | 18-19 | 8-10 | ||

| 1.4948 | 304H | 08Х18Н10 | 0,08 | 2,0 | 0,75 | 18-20 | 8-10,5 | |||

| 1.4306 | 304L | 03Х18Н11 | 0,03 | 2,0 | 1,0 | 18-20 | 10-12 | |||

| A3 | 1.4541 | 321 | 08Х18Н10Т | 0,08 | 2,0 | 1,0 | 17-19 | 9-12 | 5xS-0.7 | |

| A4 | 1.4401 | 316 | 03Х17Н14М2 | 0,08 | 2,0 | 1,0 | 16-18 | 10-14 | 2-2,5 | |

| 1.4435 | 316S | 03Х17Н14М3 | 0,08 | 2,0 | 1,0 | 16-18 | 12-14 | 2,5-3 | ||

| 1.4404 | 316L | 03Х17Н14М3 | 0,03 | 2,0 | 1,0 | 17-19 | 10-14 | 2-3 | ||

| A5 | 1.4571 | 316Ti | 08Х17Н13М2Т | 0,08 | 2,0 | 0,75 | 16-18 | 11-12,5 | 2-3 | 5xS-0.8 |

In their own way, according to the minds of the authorities, stainless steel began to be divided into several subgroups, designated in the first century:

* - designated subgroups of stainless steels:

- A1, A2, A3, A4, A5- Austenitic stainless steels - of the glacial type, non-magnetic or weakly magnetic steels with the main composition of 15-20% chromium and 5-15% nickel, which increases the resistance to corrosion. Stinks respond well to cold processing with a vice, thermal processing and boiling. Indicated by the cob letter " A The austenitic group of stainless steels itself is the most widely used in the industry and in the production of fastening.

- Z 1- Martensitic stainless steels are significantly harder than authentic steels and can be magnetic. They are marked by hardening and release, similar to simple carbon steels, and are found to be hardened as a main component in prepared cutlery, cutting tools and annealing machines. More susceptible to corrosion. Indicated by the cob letter " Z"

- F1- Feritic stainless steels are richly soft, lower martensitic with little carbon instead. The stench also has a magnetic power. Indicated by the cob letter " F"

Austenitic stainless steels of subgroups A2, A4 and others

Marking system for austenitic stainless steels with the letter " A Divided in Nimechchina for easy marking and fastening. Let's sort the report austenitic steels into subgroups:

Subgroup A1

Steel subgroups A1 characterized by a high degree of sulfur and, therefore, the most susceptible to corrosion. Become A1 have high hardness and wear resistance.

Use for the preparation of spring washers, pins, various types of cotter pins, as well as for loose fitting parts.

Subgroup A2

The subgroup of stainless steels that is most widely expanded during fastening is A2. These are non-toxic, non-magnetic, hardened, corrosion-resistant steel. They are easy to cook and don’t melt when you eat them. Most steels of this subgroup are non-magnetic, but they can exhibit magnetic power as a result of cold mechanical processing - volumetric stamping, heading. Has good resistance to corrosion in atmosphere and clean water.

Fastening and strengthening of steels A2 Not recommended for vicinity in acids and chlorine media (for example, in swimming pools and salt water).

Fastening from steels A2 Retains potency up to temperatures of - 200˚C.

In the German classification DIN A2

- DIN 1.4301 ( American equivalent AISI 304, Radyansky closest analogue 12Х18Н10),

- DIN 1.4948 ( American equivalent AISI 304H, Radyansky closest analogue 08Х18Н10),

- DIN 1.4306 ( American equivalent AISI 304L, Radyansky closest analogue 03Х18Н11).

For those who are on bolts, screws and nuts marking A2, then, most likely, this fastening is made from one of these three steels. More precisely, as a rule, it is important through those that the manufacturer indicates without labeling A2.

All three are now included in the subgroup A2 do not take revenge on your warehouse Titan ( Ti) - this is connected with this, which is steel A2 Basically, parts are made using the stamping method, and the addition of titanium to stainless steel significantly reduces the ductility of such steel, and, therefore, such steel with titanium is very difficult to stamp.

Pay attention to the numbers 18 and 10 assigned to Radiansky 12Х18Н10 analogue steel DIN 1.4301. On the stainless steel, Import Vobronitvva often itchs, cognizen 18/10 - Ts, ni Shi Insche, yak Steakochene cognized stainless steel. DIN 1.4301.

Become A2 often sintered for the preparation of utensils and elements of grub production - the popular name for such steels is closely related to the area of smelting of steels. A2- "grub stainless steel." Then the Smislov rogue appeared. The name "harvest stainless steel" is associated with the area of stagnation, and not with the authorities of the steel A2 However, the name is not entirely correct, since titanium itself has antibacterial powers - and only stainless steel that is in stock, titanium can rightfully be called “grub”.

Fastenings from stainless steels subgroup A2 Mothers can exert magnetic power in strong magnetic fields. The subgroups became themselves A2 Non-magnetic, magnetism appears in bolts, screws, washers and nuts as a result of the stress that develops during cold forming - stamping.

The manufacturing plant, such as utensils and fastenings, can be made from stainless steel, which is additionally alloyed in very small quantities with some elements, such as molybdenum, giving its products special survivable powers. The process can be carried out only for additional spectral analysis in the laboratory - the distiller himself can consider the warehouse to become a “commercial prison” and indicates, for example, A2.

Subgroup A3

Steel subgroups A3 similar powers to steel loom A2, or additionally alloyed with titanium, niobium or tantalum. This enhances the corrosion resistance of steels at high temperatures and provides spring strength.

Used when preparing parts with high rigidity and spring power (washers, rings, etc.)

Subgroup A4

Another broad subgroup of stainless steels for fastening - subgroup A4. Become A4 Their properties are also similar to A2 steels, but are additionally alloyed with 2-3% Molybdenum. Molybdenum contributes to steels A4 significantly greater corrosion resistance in aggressive media and acids.

Fastening and rigging from steels A4 It is good to withstand the flow of chlorine-based media and salt water, and is therefore recommended for use in a vessel.

Fastening from steels A4 Retains potency up to temperatures of - 60˚C.

In the German classification DIN coming from the table, such steel A4 can be classified as one of three stainless steels:

- DIN 1.4401 ( American equivalent AISI 316, Radyansky closest analogue 03Х17Н14М2)

- DIN 1.4404 ( American equivalent AISI 316L, Radyansky closest analogue 03Х17Н14М3)

- DIN 1.4435 ( American equivalent AISI 316S, Radyansky closest analogue 03Х17Н14М3)

Remnants of the subgroup A4 May have increased corrosion resistance not only in the atmosphere or water, but also in aggressive media - that’s the popular name for steel A4"acid-resistant" or also called "molybdenum" instead of Molybdenum in the steel warehouse.

Stainless steel subgroups A4 Magnetic power practically does not exist.

Resistance to the infusion of external minds of different media on the stainless steel fastening is determined by the "statistic" "

Subgroup A5

Steel subgroup A5 May power similar to overnight steel A4 and with steels A3, the fragments are also additionally alloyed with titanium, niobium or tantalum, and other high-grade materials instead of alloying additives. This particularity is given to steel A5 Increased resistance to high temperatures.

Steel A5 just like that A3, it has spring power and is stiffened to produce a ribbed fastening with high rigidity and spring power. What is the effectiveness of fastening to steel? A5 preserved at high temperatures and in aggressive media.

Hardening of stainless steels for the production of fastenings

Here is a short table of the most widespread types of fastening and similar types of stainless steels:

| Name of fastening | Subgroup of steels | DIN | AISI |

| A2, A4 | |||

| A2, A4 | 1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4435 | 304, 304Н, 304L, 316, 316L, 316S | |

| A2, A4 | 1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4435 | 304, 304Н, 304L, 316, 316L, 316S | |

| , | 1.4122, 1.4310 | 440A, 301 | |

| 1.4122, 1.4310 | 440A, 301 | ||

| 1.4122, 1.4310 | 440A, 301 | ||

| A2, A4 | 1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4435 | 304, 304Н, 304L, 316, 316L, 316S | |

| A2, A4 | 1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4435 | 304, 304Н, 304L, 316, 316L, 316S | |

| A1, A5 | 1.4305, 1.4570, 1.4845 | 303, 316Ti, 310S | |

| 1.4122, 1.4310 | 440A, 301 | ||

| A1, A2 | 1.4301, 1.4306, 1.4948 | 303, 304, 304Н, 304L |

The same types of fastenings can be produced by manufacturers from other, different types of stainless steel grades with minor additional “secret” alloying additives to give specific properties to the steel. For example, retaining rings can be made from such a “special” stainless steel subgroup. A2, as a commercial secretory of the winegrower.

The widest stainless steels

Below is a complete table of the widest types of stainless steels and their correspondence to different classifications of standards.

Designation of chemical elements in the table: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||