Combined prefabricated-monolithic foundation. Precast monolithic foundation. Organization of the work of workers from the installation of prefabricated elements

The foundation is the basis of the structure that transmits the desire from the new to the ground. The prefabricated stitch foundation allows you to build both light-weight buildings such as private cottages and large-scale buildings.

Monolithic and prefabricated string foundations

Depending on the method of organization, monolithic and prefabricated foundations are divided.

To create a monolithic stitch base, it is necessary to construct a frame from woven metal reinforcement. Yogo is poured with concrete.

Preparing a monolithic stitch is more labor-intensive and takes more than an hour. It is necessary to create formwork, a reliable frame, and a concrete mix.

The prefabricated azed-concrete strech foundation, instead of a monolithic one, is collected from azed-concrete concrete blocks - blocks. In this case, the blocks are also tied together with additional reinforcement and poured with concrete. You can also say that this is a prefabricated monolithic foundation.

Nowadays, instead of metal reinforcement, more and more often, light-weight, and not less valuable composite fiberglass runners are used. Such fittings have significant advantages over metal ones. It is absolutely resistant to corrosion and resistant to various aggressive media.

Such a composite rod is 5 times lighter, with a lower diameter similar to metal. The base for the booths with this type of reinforcement is very light, the bottom is a reinforced concrete foundation. As a result, the pressure on the ground is significantly reduced.

The problem with organizing a collected stitch is that the BWs come in standard sizes, which is important to select. In addition, reinforced concrete blocks are subject to significant moisture, so their installation can require expensive lifting equipment.

Drilled and buried base

The depth of foundation formation depends on various factors. The most important thing is that there is no need to create soils. On heaving soils (which significantly expand and contract when they are frozen and soaked), it is customary to install supports that are buried in the soil, so that they are 30-50 cm lower when the soil is frozen.

The depth of foundation formation depends on various factors. The most important thing is that there is no need to create soils. On heaving soils (which significantly expand and contract when they are frozen and soaked), it is customary to install supports that are buried in the soil, so that they are 30-50 cm lower when the soil is frozen.

In addition, an important role in choosing the depth of the foundation is played by the soil structure that will be placed on the foundation. Under light soils on slightly heaving soils, you can organize a base with slight embedding (especially due to freezing).

In Europe, in dostially cold Norway and Sweden, since the 70s of the last century, a system has been developed to protect crushed foundations from frost heaving of the soil. To do this, organize insulation of the very foundation and the ground below.

This method should be used in Alaska, where the average temperature becomes +2°C. Unfortunately, our technologies are still practically impossible to achieve.

Rules for laying assembled stitch elements

Under the string foundations, a trench is dug in such a way that its bottom is 100 mm lower than the bottom of the base. For such a task, it’s worth paying for a thick pillow and blocks. Carefully compact it and pour water on it.

The width of the trench, and therefore the foundation itself, is due to the fact that the width of the conveyor walls is also 100 mm wider.

In order for the prefabricated-monolithic foundation to be laid as quickly as possible and with the least amount of materials wasted, it is necessary for the mother of the chair. Obviously, the number of blocks needed to be insured is necessary. This is a document confirming that installation work is being carried out. On the chair, the layout of the blocks is indicated and the place where the monolithic or often plot will be built is indicated.

Sticks between blocks in one ball are laid with a concrete mix. The scheme for laying the balls of the stitch is checkered in relation to the front blocks. The balls are tied together for the same cement break. This product is no larger than 30 mm.

A reinforced mesh can be placed on top of the skin ball before pouring concrete. Ale tse obov'yazkova umova is deprived of rich top-of-the-range wakefulness.

Particular attention is paid to ensuring that the balls are perfectly horizontal when laying prefabricated stitch foundations. When doing this, check the horizontality of the skin block. At the edges it is necessary to work on retying the reinforcement. Where should the foundation be laid?

The foundation must be at least 100 mm high above ground level. Apply reliable waterproofing insulation on top of the lining, and paving along the perimeter.

The most popular foundation for private living is the strichkovy one. This is one of the largest plastic foundations that can be designed for any kind of soil. A wall is laid around the perimeter of the supporting partition, through which the stitch appears. The transverse section most often has the appearance of a rectangular parallelepiped, sometimes with a wide base, sometimes without. The width of the stitch in any case may be the same. The depth of the foundation is determined based on the type of foundation chosen, climatic factors, the type of soil, the geological conditions of the groundwater level and the level of groundwater. The axis of all these factors together indicate the parameters of the stitch foundation to the foundation.

It is not advisable to work on unstable, water-saturated, highly heaving soils with great freezing depth (more than 2 meters). It can be designed, but it can be designed even more richly. The stench is not suitable for peat or forest soils. Consider other types of foundations for such minds. Also, don’t forget to use stitches for light beds - frame or wooden: for them there is a cheaper, but no less reliable type - parts or finger. In the case of fallouts, a strip foundation is most often the best option.

Vikorist is not less useful for everyday life. It’s worth it to pay attention to the parking lot, garage, capital outbuildings at wake-up time.

The strichkovy foundation is very plastic - it can be developed under any form of everyday life, given any form.

Project: write a word

Living in a living room will require a lot of money. Naturally, the blame is due to the need to protect. But the foundation is not the right stage to save money on, and even the wrong decisions will lead to problems that will require a lot more pennies. Therefore, it is necessary to complete the project, as well as geological research.

You can do without this step at any time during the wake-up hours of small weekdays, laženya, hourly watches and government wake-ups. If there will be a capital booth, and made from important materials, then the vests must be large. Well, please tell me.

This information is sufficient for independent design of foundations, especially string foundations. If marriage is known, it will often lead to two extreme results:

- The foundation is built on a supernatural reserve of value for these minds. This is good from the point of view of operation, but not from the point of view of increased costs, which often exceeds the risk of design.

- Insufficient reserves or incorrect design, which led to an uneven siege of the soil. As a result, there are cracks in the walls of the hut.

As you know, resentment options lead to the overexpense of costs: at the stage of daily life or for renovation and repair. And it’s not a fact that project robots cost more. Quickly on the fly. Roofing the foundation will cost approximately $100-250, but for additional geological data, the cost will be around $1000. For a small case, you can carry out the investigation on your own, but for a larger case, it’s better to trust the professionals.

Types of string foundations and their vikoristanya

When using a string foundation, several types of materials may vary, and the names, as well as the features and technologies, obviously change. What remains unchanged: digging the foundation pit and preparing the foundation. Other steps are subject to change. Briefly the tipi can be described as follows:

- When the concrete is removed and the reinforcement is removed, the foundation is called monolithic. All robots are registered on the daily Maidan. Next to the dug pit, formwork is installed - a prefabricated structure that gives the shape to the concrete excavation. Then they lay and tie the reinforcement, then fill it with concrete. For advanced technology, the term of operation is approximately 100-150 years. Therefore, they can be distinguished from materials, the term of operation of which can be equated with the named interval. There is a lot of time spent on all the work: assembling the formwork, binding the reinforcement, pouring and trimming. This is all troubling.

- Prefabricated concrete slab foundation. It is constructed from reinforced concrete blocks, which are formed at the factory. The stink of two tipis. Trapezium-like (also called a pillow) are laid down, and foundation wall blocks (FBS) are installed on them in one or several rows. The stinks are connected with each other like reinforcement, the gaps are filled with rubbish. The term of service is about 50-70 years, which can be compared with the term of service of frame booths. The work required for this option is much less (a few days), but in most cases you will need to rent an overhead equipment - a winch for small buildings or a crane for more serious projects. In this case, it is necessary to remember that the value of a precast foundation is 20-30% lower than that of a monolithic foundation, which means they cannot stand on heaving or subsidence soils.

- Pobutovy strichkovy foundation. They will be made from natural rubble stone. Some with viscous concrete and some without. When choosing concrete, talk about a rubble-concrete foundation. This signifies great satisfaction and high qualification of the workers: the stone is placed correctly, and is also associated only with the owner. Such foundations can be built on stable, non-heaving foundations, otherwise there is a high risk of cracks being repaired or permanent destruction. The term of service is like that of the collected 50-70 people.

- Single-stitch foundation. This is another option for a prefabricated foundation. In this case, most often, a monolithic line with an armored belt is poured around the perimeter of the foundation, and the wall is folded together. Sometimes, instead of targeting, vicoristic blocks are used. Wart that the entire blocks are hygroscopic and may not last the longest term of service. For reliability - not the most problematic and short-lived foundations: the term of their service is 30-50 years, and not with proper design and construction.

The single-minded foundation is not very popular today: high labor intensity and low service life are the axis of the main reason

Most often, a monolithic stitch foundation is used. Although it is the most labor-intensive, it has a single design that redistributes the importance. That's why he often works on heaving soils. If the soils are dry and reliable, a reinforced concrete precast foundation can be installed. It often takes great effort, but everyday life requires less than an hour, which is also important.

Rubble and rubble concrete foundations are built mainly in regions with a sufficient amount of supporting material - in Girsky or close to them. There, first of all, there are ideal ones for them, in another way, they are the filthy fakes, who are competently created robots. In the lowland areas, stone delivery is unprofitable, and you won’t find another master.

The solid foundation is rarely shaken the rest of the time. Despite the extreme accessibility of the material, it does not have the best characteristics and will require significant investments in the organization of waterproofing, as well as insulation. As a result, his skill grows richly. With a short term of operation, it is completely unsuitable to run on resistant soils.

Slab foundation

Yandex.Direct

The slab foundation has a rigid structure - a monolithic slab reinforced with metal mesh. The thickness of the slab can be 25-40 cm, and the depth of the backfill can be determined by hydrogeological minds. When laid deeply, the foundation slab will be under the basement. It is also possible to place the slab directly on the surface of the earth. At this point, the foundation slab also serves as a base for placing the first one on top. In this case, the insulation is transferred both around the perimeter and along the entire surface of the subfloor. In the event of great savings, the concrete foundation slab can be replaced with a simple one, the supporting area of which concrete can be constructed accordingly. The slab foundation simultaneously serves as a base for the foundation - first on top or in the basement.

Washing of a monolithic reinforced concrete slab foundation

| Get ready and celebrate the Maidan |

The base is covered with sand and thoroughly tamped, pouring water |

|

The Maidanchik will be reinforced with reinforcement, the connecting struts will be cross-linked in places |

Concrete is poured evenly, shaping the entire ball with a shovel |

|

To create a uniform ball all the time, use a vibration installation |

The finished foundation can stand without any damage |

Do not be distracted by the monolithic belt. A prefabricated foundation is more resistant to deformation due to uneven subsidence of the soil, so a monolithic reinforcement belt should be created on top of the prefabricated foundation blocks. This is especially true when building a cabin with walls made of porous concrete, ceramic blocks, or otherwise unreliable soils.

Rubble masonry foundation

Foundations made from rubble masonry are recommended for small (up to 1 m) installation depth. Vikorist torn stone - rubble, which is selected one by one, filling the empty seams with concrete. The material is laid opposite the walls of the trench. The outer rows of the masonry will be made of large stones, and the gaps will be filled with smaller ones.

Rubble masonry foundation

The masonry is carried out using re-tied seams. This is a laborious process, but does not require much strength to the concrete. In general, concrete can be prepared independently. Prefabricated stritch foundation

Design of a prefabricated stitch foundation

Prefabricated strech foundations are constructed from ready-made reinforced concrete slabs and blocks. The slabs are formed into a trapezoidal shape, forming the lower part of the foundation - a pillow. The cushion slabs are installed on a prepared base made of sand or gravel, 100-150mm thick. On the upper surface of the pillow there is a concrete belt reinforced with mesh reinforcement, approximately 50 mm thick. Next, the foundation blocks are installed with additional ligation of the sutures (cutting the skin on the next row of blocks). In some cases, in order to increase the strength of the structure, the rows of blocks are reinforced horizontally. Create a 20mm gap between the blocks to fill it with concrete. The upper surface of the foundation wall, like the base, is covered with a reinforced concrete belt. Before the hour of waking up at the walls of the foundation, it is necessary to provide openings for the laying of communications. After the pipes are laid, the stench really settles down.

The technology for constructing a prefabricated string foundation is simpler than a monolithic one - daily work on the construction and dismantling of formwork (only the pouring of reinforced belts). In connection with this, the quality of a precast foundation is lower than that of a monolithic foundation by approximately 20%. Ale during this installation there is a required faucet. The prefabricated strech foundation is made up of several elements, so its device is not recommended on heaving soils, such as clay and loams, where fragments can move the blocks. Whose main shortcoming is between the equal and the monolithic one. For the minds of life on rich soils and proper desalination, it will be healthy and long-lasting.

studfiles.net

How to build a monolithic foundation: types, technology, devices

Pros and cons of monolithic foundations

What is the foundation of vibrati? This food benefits all forgetful people, regardless of the characteristics of the job and financial capabilities. Why does the choice most often fall on the monolithic version, regardless of the higher price? The budget will last forever, and no one wants to constantly fight for its savings. Monolithic foundations are reliable and durable. There are no problems with the choice of materials for walls - timber, blocks, frames, frame structure - a monolithic foundation can “endure” everything. The margin of reliability is such that monoliths will often be made with your own hands without a project.

Several types of monolithic foundations:

- Strichkovy. What type of embarrassment and misalignment are there? The stinks are eliminated by the depth of the soil (depending on the characteristics of the soil) and varnish. For such a foundation, dig a trench, excavate the foundation, install formwork and reinforcement cage. Then pour the concrete.

- The monolithic slab foundation also has options: it can be laid on the surface of the ground or in a pit. In another case, we remove the booth from the basement top, but at a higher price. It is difficult to build a monolithic slab foundation: a slab of reinforced concrete is laid on a flat, compacted platform made of gravel and gravel. If necessary, insulate and stop drainage.

- The Swedish stove is insulated - a more thorough variety. All engineering communications, including thermal underlays, are laid strictly according to the design and filled with concrete.

- Before monolithic foundations, with certain amendments, it is possible to add a prefabricated monolithic foundation and a similar foundation using the TISE technology with a grillage. At the first step, fill in the original crushed line and place a base from factory blocks on it. For good soil there is a possible and reverse option - first blocks, then a reinforced concrete belt.

TICE technology is used to protect land productivity. The pits under the pillars should be drilled with expansion at the bottom (the support area increases), and the top of the pillars should be tied with a concrete grillage. There is an intermediate option between a basic and a string foundation.

When selecting the foundation, take into consideration the depth of your mind: the soil is stored, the depth is frozen and saturated with water. It is necessary to realize that there are no bad foundations. Є foundations that do not correspond to the characteristics of the soil. Therefore, in cases of serious illness, consultation with a doctor is necessary. Based on engineering and geological research, the best option for efficiency and reliability is determined.

What are the benefits of monolithic foundations?

- Your hopelessness. It is a single structure (poured in one go) without seams and empty.

- The reinforcement frame distributes the reinforcement step by step throughout the entire foundation.

- An uneven influx of forces of swelling “takes shape” in the minds of the minds (align with this foundation!).

- There is no limit to the choice of material for the walls, both in terms of size and size.

It should be noted that the structure of the monolithic foundation should be of this type. The skin foundation is covered with a cushion of sand and crushed stone, reinforcement is tied into a frame, formwork is placed in concrete. All the food is in how you put it all together.

Let's take a look at the main options for "laying".

Do-it-yourself stitch foundation

Rumors and the emergence of new options for the foundation have led nowhere: the most popular foundation is being deprived of the most popular. What's new about it? There are three words to sum it up: reliable, inexpensive, simple. It’s so simple that most forgetful people undertake to fill this monolithic foundation with their own hands, without any special everyday skills.

Let's look at the daily life of the fundamental line step by step and report.

- Development of the project. Let's face it, right Qia is not cheap. Therefore, the plan is to entrust the representatives with two problems: important minds in the business and nowhere for money to go. It’s easier to deal with the situation on your own – forums, where self-propelled people can share information and knowledge if they want to row the boat.

- Layout of the foundation. The removal of the project (either its own or its disintegration by the representatives) should be transferred to the future Maidan as accurately as possible. With special respect, be careful about straight cuts and dotrim linear dimensions.

- The earthly robots begin from the removal of the algae ball: they do not take care of the expansion of the clay and will not give us anything other than excess algae to rot under the booth.

- Soil removal can be done manually or using machinery. With your hands, more precisely, or more forcefully, additional working power is required. After the excavator, everything will have to be repaired. The method of preparing the trench is up to you.

The depth of the trench should be kept below the ground: for a deeply buried foundation – 0.6 -1.0 m, for a buried foundation 20-30 cm below the level of freezing of the ground. The original thickness of the monolithic foundation is 30-40 cm.

- Place a 15-20 centimeter ball of sand near the trench, pour it with water and tamp it down. The cushion will be clear and durable if it is placed on a geotextile ball: it will resist sand.

- The further walls and bottom of the trench are hydroisolated with roofing felt or polyethylene pellet. This is how they avoid the Swedish winter of the laid concrete.

- The formwork is assembled above the surface of the earth and the walls are firmly secured.

- Knit the frame from the reinforcement. There must be at least two rows of late-spun rods (at the bottom of the stitch), connected by transverse and vertical cuts. The diameter of the reinforcement, the methods of connection, and the placement of the reinforcement are subject to specific considerations. It is important for your mother to have a guide at hand, and not blindly trust articles on the Internet.

- Once again, check the correctness of the formwork installation (dimensions and reliability).

- The pouring of the monolithic foundation is completed in one step, the concrete is compacted with a vibrator. This is the shortest way to achieve monolithicity.

- During the hardening period, the concrete is covered with a ball of thyrsi and periodically watered with water. After 3-4 years, you can restore the life of the walls.

How to build a monolithic slab foundation

Without replacing the stitch foundation, you will be able to guarantee 100% reliability with a new profile. Peat bogs, clayey soils, saturated with water, are absolutely safe to deal with when frozen. The foundation is subject to enormous wear and tear and may become deformed. This is how a monolithic slab works: it is not for nothing that it is called a floating foundation. Lie on a ball of sand and crushed stone and the entire surface receives pressure from the ground when it freezes. The rigid frame evenly distributes the pressure from below to the animal (the vagina), compensating for the forces of swelling.

The technology of a monolithic foundation such as a slab and an insulated Swedish slab is not much more complex than others, but there are many more advantages.

You will have to go through the stages themselves: design, earthworks, cushion, waterproofing, reinforcement, formwork, laying concrete.

When designing, insure the surface area, the thickness of the slab, the quantity and size of the reinforcement, the grade of concrete and its thickness. Don’t forget about drainage ditches and insulation with polystyrene foam (in the lower areas).

Laying out the slab is not difficult: a straight-cut pedestal the size of the axis and all the markings.

Earthling robots can be carried out manually and quickly with a bulldozer. Over the course of several years, robots move their native soil (perhaps for good?) and revive the plot.

The Maidan is covered with geotextiles and sand and crushed stone are poured into balls. You can also ram it manually, you can use the technique.

For waterproofing, lay any roll materials in two balls with sealed sticks and outlet from the sides along the circumference. The excess is used to cover the ends of the slab.

The stepping ball is thermally insulated with polystyrene foam sheets. Non-language stage for wet areas.

The formwork consists of one wall, installed around the perimeter of the foundation.

Reinforcement of a monolithic foundation is a bonding process. For the slab, the frame is formed into two mortars with a square center of 20 cm. The skin from them is laid 5 cm above the surface of the slab.

Equal quality of monolithic foundations

The importance of skin type foundation has long been promoted by lifestyle companies. Let's kiss and kiss.

From the monolithic foundations we looked at, the cheapest laminated struts. It dawned on me: there is little waste of earthen work, waste of materials and concrete.

It costs a few dollars for a monolithic slab. Moreover, its quality increases proportionally to the surface, not only does it increase the loss of concrete. ale and reinforcement, sand and crushed stone.

The foundation of TICE is advancing behind the war. It is followed by a price stripe. Prefabricated-monolithic is already two-way road, embedding stitches - morning.

The price of your foundation may not be worth a whole lot. Maybe you have your own excavator - minus the versatility of earthworks. Having a lot of relatives and friends means saving on labor. The more parameters you use when folding the curtain, the more accurate you will be.

stroymore.ru

Monolithic reinforced foundation: stages of construction

Before starting work, it is necessary to know what type of soil it will be on which it is planned to build a monolithic foundation.

For any dispute, the terms of operation must first be determined by the value of the non-structural structure. The criteria that determine the durability of a plumbing infusion are, first and foremost, the ductility of the materials that are used for the foundation, the reliability of the material, good hydro-thermal insulation, as well as the correct choice ir type of basis.

What is a monolithic stitch base?

Basically, the repair of such foundations is planned for such structures, where they have the fate of delivering important materials, such as concrete, stone, adobe, etc. This type of load-bearing structure has not only increased strength, but also great reliability, which can be enhanced by using reinforcement. In this case, the potential of a modern monolithic foundation is high, since a large number of building materials are necessary for its construction. It makes sense to stagnate such a foundation unless it is buried: this will not result in a significant increase in costs. This choice is especially relevant when building huts where basement or basement spaces are planned, such as those installed on a slab, for a hut with a basement.

A monolithic reinforced concrete foundation should not be insured without showing the thickness of the soil in the area for everyday life. At the current base, the width is significant due to the level of emphasis on the slab, and there, at its core, depends on how many walls there are in the future, how many surfaces, and where it is planned to combine the substructures there will be no basement. A reinforced foundation is considered to be the most reliable foundation; when planning, it is necessary to look at the reinforcement.

The architecture of the booth conveys a victorious monolithic monolith in the form of a reinforced concrete slab or box over the entire area of the building. It is trapped so that the reinforcement of load-bearing structures on the pallets with viscous stubs is formed. The expansion is usually carried out within a 1 m section, and the tension remains approximately the same throughout the entire structure.

Turn around to the spot

How to unravel the strip foundation?

With the construction of such a structure, I first need to choose which one is to blame for the sinking of the string foundation. This indication for the skin is individual. First, a two-meter pit is made, which will help determine the structure and softness of the soil, the depth on which underground waters lie, and the level of freezing. In this case, the primary reference point is the degree of heaving of the soil. If the soil is of a non-heaving type, the foundation for the cabin or cottage can be laid on any depth regardless of the level of freezing.

The depth for heaving soils will be a little more complex, and in addition, a lot of additional adjustments will be required. When the groundwater level is located at a distance of 2 m or more above the surface, it is possible to install a finely buried base. Since this area is slightly larger than 2 m, it is necessary to further bury the string monolithic foundation at the same height as the frozen ground. If underground water is present beyond this level, it is necessary to pour a monolithic string base onto this depth, if not more.

If the required depth of foundation for a non-bearing structure is determined, you should think about selecting the material from which you plan to prepare the foundation. To fill such a base, you can quickly use rubble concrete or rubble masonry. For rubble masonry, you can use stones of any irregular shape. It is necessary to repair and possibly reinforce the equipment.

For a stitch foundation, the width should be no less than 0.5 m. The filling technology is used to change the width of the stitch, which will increase the thickness of the foundation walls by 5-10 cm. The deeper the foundation is laid, the greater the difference between the foundations. With a different stitch. To properly lay a strick foundation at a depth of 1 m under a single surface, it is necessary to lay slabs 25 cm wider than the width of the wall.

A monolithic base made of rubble concrete should be no less than 35 cm in size. This base has many advantages: it can be laid on any type of soil, and when built, there will be fewer difficulties. However, when damping a non-section structure of this type, excessive damage to the concrete is avoided. To create such a foundation near the slab, you will need formwork to be installed in the trench. After this, the flood of moisture begins.

Turn around to the spot

Stitched monolithic foundation: stages of viconny

Before you begin laying the foundation, you will need to align the trench according to the plan. When digging, it is important that the value of the walls is preserved as much as possible. This is best done, as a rule, on viscous soils: in this way, the walls can be built virtually vertical, so that in cross-section they represent a trapezoid or rectangular structure, which can be used as a formwork structure for the slab. Sometimes the greatest depth of the trenches that are prepared will increase by 1-1.5 m, depending on the type of soil.

When pouring a monolithic string foundation, since there is reinforcement in it, it is necessary to protect the water from it so that the reinforcement does not get stuck by the soil. First, remove the reinforcement from the bottom, then plaster the adjacent plots; when digging a trench, the earth must fall out onto the mountain side. It is necessary to select soil masses up to the lower icons on the chair. Since in the foreground the cabin has been supplied with water supply, it needs to be repaired.

Since concrete reinforcement is formed independently, the reinforcement can be installed simultaneously from the formwork. The fittings are welded and connected together. Proper reinforcement will enhance the service life of the foundation. When the reinforcement is installed, the frame for which the reinforcement is installed is made of at least 2 rows of vertically extended runners.

When building a monolithic foundation, it is necessary to install spreaders, racks and shields in the back of the twisted trenches. Plastering the formwork before waking hours on clay soils is especially important. If the structure, which is not supported, is poured at great depth, the formwork panels can be rearranged. It is his responsibility to adhere to the rules by which cold joints and working joints are made during concrete pouring.

When laying a prefabricated-monolithic stitch foundation, the slid blocks should be laid in front of the concrete foundations. Plating of the precast foundation is carried out in several stages. Concrete blocks are prepared in a factory way: they need to be loaded into a vehicle and transported to a plot designated for use. Vivantage of blocks should be removed using the help of a water tap. Ideally, the crane is useful when laying a non-supported structure: the skin from the blocks is raised above the ground and installed on a prepared site.

The vlashtovoy rubble base, the prepared stone should be placed in the groove exactly according to the dimensions. They do not require grading, the concrete does not require bonding of joints before they come out. If it is assumed that the pouring of the concrete mix will be interrupted for 6 years or more, the ball of the top stone of the pouring will be only half done. Restarting the work will be necessary due to the stagnation of the structure, which will allow the installation of stones without compaction. In this case, the non-structural structure will be built according to SNiP.

With a reinforced foundation, the formwork structure must be removed after 1-1.5 cycles. When ready, concrete slabs need to be soaked in water every hour, and then covered with burlap or matting. During the operation, heat and waterproofing of additional materials such as those made from bitumen or warehouses was carried out. This is necessary in order for the life to fully comply with GOST requirements.

Turn around to the spot

Advantages and shortcomings of a monolithic stitch

The main disadvantage of using a single-piece monolithic slab is that it is very durable. Moreover, on soils such as driftwood or peat, this option is difficult. For them, it is necessary to use some other option for laminating a non-bearing structure: for example, to install the base on the joints.

And yet, the string foundation has no obvious advantages over other structures that need to be built. From a technical point of view, the slabs should be sunk after an hour and completed with the worst option for plastering the base, especially the reinforcement. The Vikonan armature allows heavy-duty equipment to remain on the stand so that the building can remain standing for a long time. It is important that the string foundation can be molded into a sufficient shape, so that the reinforcement is lighter.

moifundament.ru

Precast-monolithic foundation on scaffolds

Warm composite foundations based on prefabricated monolithic slabs (SMP) are installed on screw or reinforced concrete beams. The technology has become stagnant among many people in everyday life and has proven itself well in private life in Western Europe.

Technology advantages:

- Saving hours at the zero stage of everyday life Easy installation and high mixing density - 100 sq. m "turnkey" in 3 days

- High value High value of slabs

- Handiness Installation of a combined foundation does not require preparatory work or acquisition of important equipment

Warm foundation on screw or reinforced concrete pallets

A warm foundation is optimally suited for the construction of living and guest cabins made of any material, including foam block or aerated concrete. Before that, such a foundation can be laid for a mansion, a garage, a government dispute, etc. A qualified team will install warm combination foundations in accordance with the needs of the contractor:

Easier folding of re-crits

- The precast-monolithic slab consists of pre-stressed beams and filling elements.

- The filling panels are simply laid between the beams

Energy efficient thermal insulation

- As a type of insulation, expanded polystyrene is used, the thickness of which is 27 cm.

- Ideally suited for installation of engineered “floor heating” systems

Concrete screed

- After installing the prefabricated monolithic slab, it is reinforced with 4 mm stainless steel mesh.

- The formwork is installed and the foundation is filled with concrete.

Features of precast-monolithic foundations on screw or reinforced concrete pallets

- Life on any landscape: with great differences in ground level, on folding terrain, in forests without cutting down trees, in marshy areas, on water, as well as on weak soils and with a high level of groundwater

- High value of overcrit: the distribution of weight on overcrit can reach 2250 kg/m².

- Energy-efficient thermal insulation: insulating elements are removed from the outside of the cabin and help maintain the optimal temperature in the room

- The trivial term of foundation service: components based on reinforced concrete and synthetic materials are practically not limited by the term of service

- Economical cost compared to other technologies for insulating foundations

Availability and prices

You can find out about the availability and prices for prefabricated monolithic foundations here:

Precast-monolithic foundations

kkzm.ru

Technology of laminating monolithic foundations |

Monolithic foundations are this type of structure, which is prepared by pouring a concrete mixture into the formwork, which is then reinforced with reinforcement. The result is a beautiful design that is designed to convey both compression and tension. For this purpose, a monolithic reinforced concrete foundation allows for a double-top structure and a rich-top structure.

The monolithic foundation is poured directly onto the building maidan with your own hands, forming a solid structure. There are no seams, just like a butt - a prefabricated FBS foundation. This ensures the durability of the foundation slab.

Advantages and disadvantages of monolithic foundations

A monolithic foundation has its advantages and disadvantages, which will allow you to better navigate the current market, and you will be able to choose which concrete foundation is best suited for your purposes.

- The monolithic foundation is enhanced by its increased importance and the ability to absorb different types of influence. These advantages allow you to conduct everyday life on heaving soils;

- The technology for preparing such bases makes it possible to create a home made with your own hands, even without the base from FBS;

- a monolithic slab can be made in different configurations, which is especially important when working with a non-standard base shape;

- The alimentary concrete foundation has good waterproofing characteristics if the insulation structure is properly constructed;

- for preparation there is no need to use expensive equipment, for which the price will be cheaper;

- As workers note that the technology is characterized by simplicity, low-skilled workers can correctly fill a monolithic slab with their own hands;

- The concrete foundation acts as a cushion, protecting the basement and basement from external factors.

- weak thermal insulation power. If you improve the thermal conductivity of concrete, you can see that the reinforcement creates “places for cold”, but the disadvantages for the construction of the structure are to maintain the set temperature;

- High level of preparation. The price depends only on the design of the base and can reach the third stage of everything. According to this plan, FBS will be much cheaper.

Varieties of monolithic foundations

The installation of a monolithic foundation can be constructed in 3 ways, which of them is better to choose - to lie under the significance of everyday life:

- stitch;

- slab;

- stovpparts.

A monolithic monolithic foundation is built to form the perimeter of the booth, as well as the foundation for the walls. This is the most popular type of foundation for building a cottage or private cabin of the double-top type with your own hands.

It conveys the power of ventilation to the basement, which can play the role of a garage or a technical room on top, which a modern cottage will require. The technology of such a basis, in order to ensure proper operation, will require the installation of a gravel cushion.

This foundation is not as reliable and valuable as his colleagues, but his daily life costs you much less. Stop concentrating at the points of greatest emphasis on the base, as well as at the walls, which are less than standard.

The coating of the slab foundation is carried out under the installation of a flat booth. Due to the large supporting area, it can highlight the great importance and instability of the soil.

The main part of the foundation slab has the ability to move simultaneously with the ground, so a monolithic slab foundation is also called “floating”. However, such a foundation cannot be laid on slopes and in places that are vulnerable to flooding - at low altitudes, such a foundation will immediately serve and continue to exist.

Technology for preparing slab foundations

Before the cob works, the first task is to carry out the development of the future structure. For this purpose, it is necessary to determine the type of soil, the depth of its freezing, the height of groundwater distribution and the climatic characteristics of the region.

Everything can be entrusted to professionals, otherwise the skill of such robots can produce positive results. Therefore, most often the foundation slab is broken with one’s own hands, leaving the large reserve of value of the slab to allow for minor damage.

In addition to the soil, the cushion, like the base of the foundation slab, is also exposed to erosion. If the soil is heaving with a high depth of freezing, then the cushion is built to the maximum flatness of the base, evenly distributing the impact on the ground.

When living on heaving soil with low GPG, it is necessary to ensure that the cushion is raised below the freezing depth. Since the soil is very shallow, the cushion is installed at any height.

The simple technology for leveling the slab base with your own hands follows the following steps:

- Before we begin, we will carry out the excavation and layout of the plot for the foundation. Uncertainties are verified by level and level. The area of the building is several meters larger than the area of the next building.

- Then you dig the pit with your own hands or using acquired equipment. It is necessary to ensure that the bottom is horizontal.

- A cushion is created to improve the durability of the slab. The sole will require viscous ramming with vibrating plates.

- The next stage is the installation of communications, such as sewerage, drainage systems and water pipes.

- Before pouring the main ball, concrete preparation is completed. Vaughn lies next to a concrete screed poured into a ball, about 10 centimeters thick, made of M100 cement. A bitumen primer is applied to the finished base.

- As a foundation, the monolithic slab is covered with waterproofing, the seams of which can be sealed with a blowtorch.

- The formwork is installed outside the perimeter of the structure.

- The design and installation of the reinforcement frame, the diameter of the reinforcement is from 12 to 16 millimeters. The center of the mesh should be approximately 20×20 centimeters.

- Filling the slab with concrete of the selected grade and strengthening it with a clay vibrator. Once the concrete has been caught, the formwork can be removed. The monolithic slab gains its full value 28 days after pouring.

Insulation of a monolithic slab foundation

This type of foundation, such as a monolithic slab, will require additional insulation.

This solution will help reduce heat loss through the stove, as well as change the subsidence of the soil underneath it. The problem of thermal insulation of the foundation is worth thinking about for residents of dry climatic regions, as well as for those whose houses or cottages are built on the ground, where the soil freezes in the middle.

You can insulate the foundation slab with your own hands either from the outside or from the inside. In case of external insulation, in order to eliminate the freezing period in non-heaving soil, insulation of the soil should be carried out under paved areas around the perimeter of the booth. The technology of insulation with polystyrene foam ensures the expansion of the given thickness of the pavement, like a butt - about 2% of the base of the building. The horizontal thickness of thermal insulation is at least not less than the vertical dimensions of the materials used to insulate.

If external insulation is impossible, the technology of thermal insulation in the middle is used for the foundation. In this case, extruded expanded polystyrene is laid on the side of the walls. The fastening material is either laid on a cement base, or mechanically fastened with further finishing.

Technology of laminating a monolithic foundation (video)

Leveling of monolithic and block foundations

FBS of prefabricated type are prepared for production and delivered to the target site. The human factor, in the absence of constant vibrational pressures, is reduced to a minimum, if the development of the so-called monolithic foundation lies only with people.

On the other hand, the prefabricated foundation of the FBS should be laid down against the weather, because The production of wine is carried out in a closed workshop. Plans for preparing a monolithic stand with your own hands can tear up the original plank.

On the other hand, when choosing a FBS, it is necessary to ensure the supply of concrete blocks, leading up to the construction site.

FBS does not interfere with the flexibility of the sphere of stagnation in everyday life, and is important for unifying everyday life.

With padded bags, if you are planning to create a hut with a unique look, non-standard shapes, then you can place it on a monolithic reinforced concrete base. The type of collected FBS is even narrower than that of the frozen one.

However, prefabricated concrete is very good for small buildings, but the expenses are not repaid by monolithic buildings. FBS allows you to build an inexpensive small object in a small area, and a monolithic foundation is suitable for building a large shopping center, or like a butt, for which you can build a large cottage.

homebuild2.ru

Precast-monolithic foundation: particulate and on a monolithic slab

Most often, a prefabricated monolithic foundation is constructed during the construction of private buildings on unstable soils or in places with a low level of groundwater. For such minds, this is the only chance for clearing the underground from above. Another reason for the development of this technology is the limitation of the term of everyday life and the need to end the zero cycle in the cold season.

This type of foundation comes in different types of stitch foundations and is divided into two possible options:

- Urivchastey.

- On a monolithic slab.

The grievances of different species are characterized by both advantages and shortcomings, which indicate their sphere of stagnation.

Monolithic slab foundation

This type of base can be obtained if standard concrete pours are thoroughly vicorized and frequently filled with sedative mixture. Here the prefabricated pillow blocks are replaced with a monolithic stitch placed under the base of the foundation. Ready foundation blocks are placed on this line every year. This design has the following advantages:

The construction of foundation-wall blocks provides the following positive power base:

- To provide special frost resistance, special additives are added to the concrete for the foundation, the proportions of which allow this material to be used in highly climatic conditions or areas with large temperature differences.

- You can increase the resistance of the material to an acidic medium by adding crushed stone, which is not resistant to the infusion of soils with increased acidity.

However, the precast-monolithic foundation has not only advantages, but also shortcomings:

- Massiveness.

- It is easy to fit a booth with a simple shape, and in case of folding architectural solutions it will be necessary to cut blocks of standard sizes.

- Mayzhe does not overcome the penetration of water.

In order to ensure maximum waterproofness of the foundation when the level of ground water is noticeably shifted in the basement area, a waterproofing treatment of the substrate is carried out, which will seal the lower part of the walls.

Pererivchasti foundations

In order to create a reworked prefabricated monolithic foundation, the required cushion blocks, wall foundation blocks, as well as cement mortar for bonding adjacent elements together. Concrete blocks are taken with an eye to the thickness of the wall. Installation begins with the installation of lighthouse blocks-pillows. With this type, put in a number of pillow blocks so that the process can be significantly shortened. In addition, the number of wall blocks changes, and, as a result, the number of seams covered with concrete cuts shortens.

However, the popularity of the stitched periodic basis is outweighed by its shortcomings - among the former, one can see increased labor intensity due to the need to twist the formwork. Klopitky also delivers sand and crushed stone, prepares and pours concrete mixes.

stroiki-doma.net

Stitches of prefabricated monolithic foundations

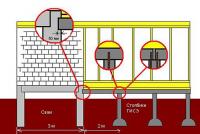

When pouring string precast-monolithic foundations, the same prefabricated elements will stiffen as when constructing overlapping precast foundations (Fig. 1). The type of concrete block is selected depending on the thickness of the wall. Prefabricated-monolithic foundations are often built according to the current technological sequence. Installation begins with the installation of FO beacon block pillows in the bunkers. After adjusting to their original design position, lay out rows of pillow blocks at intervals, either placed behind the structure or placed behind the table. The pillow blocks are wider than the rows, so that the blocks of the two walls will overlap on them. On rows of pillow blocks, FBS wall blocks are installed, the width of which can be 300, 400, 500 or 600 mm, spaced between the pillow blocks. Then, between the rows of wall blocks, the formwork panels are secured and the ball is filled with concrete of class no less than B12.5 (M150), crushing the skin ball with a vibrator. To introduce communication into the booths, open the doors in monolithic plots. For this purpose, before concreting, pipes are installed in the formwork or boxes of the required size are prepared from boards.

The solidification of the foundations of such a structure makes it possible to reduce the strength of cushion blocks by 20 -30%, and wall blocks by 50%, change the amount of seams and local laying entirely or with concrete, otherwise additional damage will occur. work on formwork cleaning, delivery of inert materials (sand and crushed stone) , cement, preparing and laying concrete mixes, monitoring the concrete, etc.

Strichkov's periodic prefabricated monolithic foundations did not find practical use in private buildings, nor in public buildings. Advantage is given to another option - a prefabricated monolithic foundation, where the basement wall blocks are spiraled onto a monolithic slab.

|  |

| Small 1. Stitched prefabricated monolithic foundation: 1 – FO cushion blocks; 2 – foundation blocks of FBS walls; 3 - monolithic concrete class B12.5 | Small 2. Stitched prefabricated foundation on a monolithic slab: 1 - base soil; 2 - a ball of sand, which is strong, 5-10 cm thick; 3 - concrete base; 4 - protinapirna adhesive waterproofing with two balls of roofing material; 5 - smooth asbestos-cement sheet; 6 - concrete base; 7 – concrete blocks of basement walls; 8 – base; 9 – perekrittya slab; 10 – insulating material; 11 - ground of the gate sizzling; 12 - concrete not paved |

| Small 3. Precast elements of string foundations: a – concrete blocks for FBS basement walls; b - blocks of a strip foundation |

When installing a string precast-monolithic foundation, prefabricated elements of the FO brand can be replaced by installing a monolithic reinforced concrete slab - a base for the basement. The foundation of the basement in this form represents the function of the foundation slab on which the walls of the basement spiral. Properly applied horizontal waterproofing of the basement base with the transition to vertical waterproofing of the walls will ensure the waterproofness of the entire structure for the obvious support of groundwater (Fig. 2).

The work with the control of such a structure on the foundation is up to date with the latest technology. If necessary, level the base with a ball of sand or 5-10 cm crushed stone. Then, along the contour of the concrete preparation, formwork is installed from the boards. Before laying the concrete with a thickness of 10 -15 cm, the base soil and formwork are filled with water and the formwork is filled to the installed mark with concrete mixture M150 (concrete class B10). After strengthening and leveling the concrete surface in a weather-resistant manner, a proper care of the concrete will be ensured, which will ensure an increase in value.

It is necessary to place the concrete base on the foundation at places where the spiral blocks of the walls are reinforced. The width and thickness of the reinforced monolithic stitch is determined by the size. In some cases, it is enough to place a reinforcing mesh with 10x10 cm centers on class AIII reinforcement with a diameter of 10 mm and a width of 1 m. After adding concrete to 50% strength, the formwork is removed, and the surface is primed, dried and glue the waterproofing insulation from two balls to the roll, scloruberoid, isol, hydroisol, etc.). The adhesive waterproofing is applied 30-50 cm beyond the concrete base so that after installing the FBS wall blocks, the waterproofing slab can be glued from the outside side and rolled out from the outside. new vertical waterproofing of basement walls. After this, waterproofing is covered with a ball of concrete or cracks, the surface of which is under the basement.

The adhesive waterproofing does not have to succumb to such pressures that stretch and stretch. To prevent mechanical damage, it must be protected and pressed with a dry structure from concrete, targets, etc. The easiest way is to protect the waterproofing with smooth asbestos-cement sheets, which are tiled before the waterproofing and fill the sinuses with soil from ball rammers (div. Fig. 2).

When the level of groundwater is at least 0.5 m lower than the base of the foundation, the adhesive waterproofing can be replaced with ball-type waterproofing with a filler thickness of 3 -5 mm. The report's isolation work is reviewed in the section “Hydroisolation of underground spores.”

| Concrete blocks for basement walls |

||||

| Type, brand | mass, kg | Dimensions, mm | ||

| Dovzhina l | Width b | Height h | ||

| FBS 24-3-6 | 1040 | 2380 | 300 | 580 |

| FBS 24-4-6 | 1300 | 2380 | 400 | 580 |

| FBS 24-5-6 | 1600 | 2380 | 500 | 580 |

| FBS 24-6-6 | 2000 | 2380 | 600 | 580 |

| FBS 12-3-6 | 500 | 1180 | 300 | 580 |

| FBS 12-4-6 | 640 | 1180 | 400 | 580 |

| FBS 12-5-6 | 800 | 1180 | 500 | 580 |

| FBS 12-6-6 | 1000 | 1180 | 600 | 580 |

| FBS 9-3-6 | 370 | 880 | 300 | 580 |

| FBS 9-4-6 | 470 | 880 | 400 | 580 |

| FBS 9-5-6 | 600 | 880 | 500 | 580 |

| FBS 9-6-6 | 730 | 880 | 600 | 580 |

| FBS 12-4-3 | 370 | 1180 | 400 | 280 |

| FBS 12-5-3 | 470 | 1180 | 500 | 280 |

| FBS 12-6-3 | 600 | 1180 | 600 | 280 |

| Stitch foundation blocks |

||||

| Type, brand | Masa | Dimensions, mm | ||

| Dovzhina l | Width b | Height h | ||

| FO 32-12-2 | 3,23 | 1180 | 3200 | 300 |

| FO 32-12-3 | 3,23 | 1180 | 3200 | 300 |

| FO 28-12-3 | 3,40 | 1180 | 2800 | 300 |

| FO 24-12-3 | 2,30 | 1180 | 2400 | 300 |

| FO 20-12-2 | 1,95 | 1180 | 2000 | 300 |

| FO 20-12-3 | 1,95 | 1180 | 2000 | 300 |

| FO 16-24-2 | 2,47 | 2380 | 1600 | 300 |

| FO 16-24-3 | 2,47 | 2380 | 1600 | 300 |

| FO 14-24-2 | 1,90 | 2380 | 1400 | 300 |

| FO 14-24-3 | 1,90 | 2380 | 1400 | 300 |

| FO 14-12-3 | 0,91 | 1180 | 1400 | 300 |

| FO 12-24-2 | 1,63 | 2380 | 1200 | 300 |

| FO 12-24-3 | 1,63 | 2380 | 1200 | 300 |

| FO 12-12-2 | 0,78 | 1180 | 1200 | 300 |

| FO 12-12-3 | 0,78 | 1180 | 1200 | 300 |

| FO 10-24-2 | 1,38 | 2380 | 1000 | 300 |

| FO 10-24-3 | 1,38 | 2380 | 1000 | 300 |

| FO 10-12-2 | 0,65 | 1180 | 1000 | 300 |

| FO 10-12-3 | 0,65 | 1180 | 1000 | 300 |

| FO 8-24-3 | 1,16 | 2380 | 800 | 300 |

| FO 8-12-3 | 0,55 | 1180 | 800 | 300 |

| FO 6-24-3 | 0,80 | 2380 | 600 | 300 |

| FO 6-12-3 | 0,37 | 1180 | 600 | 300 |

Organization of the work of workers from the installation of prefabricated elements

To ensure safe construction of the foundation, it is necessary for the foreman to work in the shortest possible time:

- install work chairs;

- divide the work among robot workers, explaining to them the technology of robotic work;

- prepare the necessary number of tools and devices required for the installation of work;

- determine the need for materials and materials;

- It means that the front is working and the rearrangement of robots is caused by downtime.

Proper placement of workers for adjacent processes and operations, preparation of the front line of work, maintaining the technological regime of finishing the work and finishing other necessary steps will ensure successful work and achievement of the delivered tasks. tribute. To install prefabricated strip foundations, it will be enough to include several individuals in the warehouse. The workers who carry out the installation of the foundation must be provided with the following tools:

- trowels – 2 pcs.;

- hand chisels – 2 pcs.;

- mounting crowbars – 2 pcs.;

- hammer-fists – 2 pcs.;

- sokira teslyarska - 1 pc.;

- mooring cord – 40 m;

- whiskey 400 g - 1 pc.;

- rhubarb – 1 pc.;

- Stalev tape measure – 1 pc.;

- scoop shovel – 2 pcs.;

- spade shovel - 1 pc.

In addition, the required slings for lifting blocks, boxes with a capacity of 0.25 -0.5 m3 for breaking, wedges for turning blocks, stakes for breaking robots, inventory portable routing, accessory for descending into a pit (trench) ).

Rubble and rubble concrete masonry of a strip foundation

Rubble and concrete masonry of underground structures is allowed to be carried out only for low-surface structures and structures of no more than 10 m. Wetting of foundations on soils for subsidence is not allowed. For rubble masonry, stone is put together in irregularly shaped slabs from clay rocks, especially vapnyaks, dolomites and sandstones. You can also use uncracked stone. The vintage value of the stone is no less than 100. The masonry is carried out in trenches or in formwork. The width of the structure made from rubble stone is no less than 60 and no more than 120 cm. The height of the masonry is up to 180 cm.

Pobutova masonry. Rubble masonry is carried out in two main ways: “under the shovel” and “under the flood”. Under the shovel, the rubble masonry is carried with a selection of stones and a bandage, in straight rows along a stretched cord. The first ball of stones is laid dry on the ground at the gap with the formwork or the walls of the trench, selecting for the largest and the largest bed of stones. Take stones into the shed with a sledgehammer or rammer. The voids between them are filled with cement mortar M50, driving crushed stone into them with hammer blows. You can split the gaps at the beginning, but then fill the beast with a layer of advanced fragility. After this, place a ball on the first row of stones and level it with a shovel. Then, having finished dressing the dressing, lay the next row of stones.

When a rubble pile is placed “under the shovel”, the stones are spherically vibrated and crushed. This promotes the value of stone structures and creates conditions for their rapid attention. The top of the skin row of stones is covered with a cut of 40 - 60 mm. The horizontality of the masonry is checked through every 2-3 rows of the rules and levels. The laying of the skin treading row begins with the installation of a great stone (lighthouses) at the corners and beams of the walls.

The rubble masonry “under the inflow” should be cured only for the foundations of the budinki with a curl of three or more than two surfaces. The looseness of the structure for such masonry may be similar to the 130-150 mm tightening of a standard cone. When laying “under the flood”, the rubble stone is laid in horizontal rows 15 -20 cm high, spaced between the walls of the trenches or formwork, without laying the verst stone, or with empty splittings. Breaks in the masonry “under the flow” are allowed only after filling the empty spaces between the stones of the top row and finishing the entries until the masonry has been dried out.

When the foundation is built on heaving soils, in order to weaken the intense forces of frost heaving, the foundation walls sound like burning (Fig. 4). To attach the walls to the foundation of the required structure, panel formwork is installed. After removing the formwork, fill the gap between the slope of the trench and the wall of the foundation with sand or soil.

|  |

| Small 4. Scheme of a rubble masonry foundation without a basement with poor walls: a – width of the base of the foundation – 60 to 100 cm; b - the width of the cut - the part of the foundation that protrudes - from 40 to 80 cm; h – foundation depth up to 100 cm | Small 5. Option for coating a rubble concrete foundation with a basement: 1 - roll waterproofing; 2 - pressed wall made of smooth asbestos-cement sheet; 3 - concrete base; 4 – reinforced concrete slab is lightened; 5 – tseglyaniy plinth; 6 – insulating material; 7 - soil of the gate sizzling; 8 - pavement |

Instead of solid wooden formwork, you can use smooth asbestos-cement sheets, which are placed in the trench after the work is completed. During the laying process, this curing allows the foundation to be given the required shape with a smooth surface and prevent cracks from spreading. In addition, if there is a need for waterproofing of the foundation, such a robot cannot be easily installed. The foundation masonry should be laid 10 -15 cm deeper than the ground level for further dampening of the base and horizontal waterproofing.

The rubble-concrete masonry is made up of a concrete mass, into which stones are sunk in horizontal rows, which are usually made up of about half the volume of the masonry. The size of the stone should not exceed 1/3 of the width of the structure. Crushed stone for concrete does not need to be larger than 30 mm. The masonry must be compacted, laid out on concrete with horizontal balls up to 25 cm thick, with rubble stones further sunk into the leather ball with gaps between them of at least 4-5 cm in height using a vibrator or rammer. Renew the rubble-concrete masonry after a 6-year break from laying the concrete, and the surface of the previously laid masonry must be cleaned with a saw and thoroughly soaked with water. The rubble stone can be lowered to the place where the crane is laid using wooden gutters of the required duration, with a crossbar of 40x40 cm. To the lower end of the gutters, nail down the wedged bars for the grouting of the stone, which is going down, and the descent is broken work on trays 50 cm wide, with sides 2 high .

Depending on the hydrogeological considerations of the plot, the design and material of the walls and other factors, when choosing a rubble concrete foundation, it is allowed to cover the basement (basement) on top. One of the options for readings in Fig. 5. Materials for varnishing the underground part of the hut are shown in the table.

Concrete storage and distribution can be selected at the table. Rozchin is responsible for such plasticity that stones would sink without compaction. Preserve the sintered rubble concrete from drying out: water it with water and cover it with matting.

| Materials for the underground part of the booth |

||||||||

| Geological minds | Natural stones with hardness not less, kg/m3 | The clay target has a thickness of 1800 kg/m3 | Monolithic and precast concrete grades | Stamps of Rozchinu | ||||

| Vapnyak - 1800 | Pishchanik, turtle - 1500 | Granite, basalt – 1800 | cement-clay | cement-vapnya | cement-food | |||

| Grunti malovologi. The level of groundwater below 3 m above the surface of the earth | + | + | + | + | 50 | 10 | 10 | 10 |

| Grunti vologi. Groundwater flow from 1 to 3 m above the ground surface | + | + | + | + | 75 | - | 25 | 25 |

| Ground, saturated with water. The level of groundwater is less than 1 m above the ground surface | - | - | + | - | 100 | - | - | 50 |

build.novosibdom.ru

L

Rectangular foundations are the most popular among all the other types of structures built up at the hour of the day, independent and above-board sovereign disputes. With all the simplicity that appears, do-it-yourself patching of a strip foundation— this is far from being a simple matter, and often, through concessions of admission to the stages of development, serious problems arise. Let's take a look further How to correctly install a stitch foundation, what needs to be worked on at any time, and what you can’t allow every time, so as not to get yourself into trouble, and also to protect your friends and acquaintances.

Types of string foundations: prefabricated and monolithic

Stitch foundations are divided into two main types, prefabricated and monolithic. The construction of a monolithic foundation is more technologically advanced, and is increasingly expanding; it will require a higher standard of workmanship, and a variety of skills (concrete joiner, reinforcement).

Underground structures can be divided into groups with different signs. The stinks come in string and stink parts, slab and fawn, monolithic and prefabricated, concrete, wood, stone and metal. However, in everyday practice, often as the basis of a building, a combination foundation is used that combines different types of structures, materials and forms. Similar schemes can be used in various situations, for example, by saving money or by strengthening the foundation.

Combination options

In the process of designing, constructing or operating a hut, there will be situations that will require adjustment of different types of foundations in one hut. The combination in this case is based on one of the following schemes:

- they are tied not with a grillage, but with a high concrete strip;

- Place concrete blocks between monolithic piles;

- the slab is not spiraled onto a soft pillow, but rather in the fire;

- the booths should be built on a line basis, and the pribudova – on solid foundations;

- Prefabricated blocks are installed on monolithic cushions.

The options for combined foundations can be greatly expanded. One of the widest options is the coating of a monolithic reinforced concrete belt along the entire perimeter of foundation walls made of piece materials. This increases the reliability of the underground structure, making it possible to connect different plots to the fire pit system.

In this type, the stitching is done with the grillage itself, but also with larger dimensions beyond the height. On the other hand, the buried footings for the string foundation provide additional support whenever it is built on a weak-bearing base or on heaving soils. The stitch parts of the design present a number of advantages, but also:

- the permissibility of building massive towers in folding geological sinks, on horizontally dry soils;

- the possibility of increased mobility and stability of steps;

- the possibility of a more equal division of the sexes;

- the activity of everyday life of booths on plots with folding relief, including on skhila.

It should be noted that the combination foundation of the string-common type has the positive power of both types of construction – string and joint parts. When this is done, the use of earthworks and the wastage of materials changes, so there is no need to remove the fragments and pour the concrete line to a great depth. Any combination of the foundation option raises problems with the ventilation of basements or basement surfaces.

The concrete blocks should be placed at the corners of the building, where the load-bearing walls are located and evenly around the perimeter of the building. The reinforcement, placed in the drill bits, runs along the entire height of the stitch and is connected to the frame. Thus, the foundation becomes a single structure.

Work on the treatment of combined foundations is carried out in several stages.

The trench is now excavated according to the design documentation, and the installation locations for the stops are outlined. Consider setting the width of the recess to 300-400mm, and the depth to 600mm. Before starting, dig with holes or vibrate the drill bits below the depth of the frozen ground. Place a firmly compacted cushion 150-200 mm thick along the bottom, install the formwork slightly higher than the top mark of the stitch or plinth, and lay the reinforcement frames on the chair. Often the structure is built with metal profile beams.

The pouring of the combined foundation with concrete is prepared in the following sequence. First fill the drill bits with any of them, intended for stops, and then stitch the formwork, without significant breaks in the work. Otherwise, the necessary value of the structure cannot be achieved.

Different schemes in one building

Sometimes the forgetters create two and three types of foundations at waking hours. This may be related to the retouching of the site, if one part is significantly lower than the other, or because of the need for the equipment to arrive at the facility, which has been in use for a long time. It should immediately be noted that decisions about such a combination and the compaction of different foundations may be praised by the fakhivs. Independent decisions without professional analysis of the situation can lead to disastrous results.

On the one hand, combining different types of foundations in one cabin allows you to protect material resources, but on the other hand, it can cause the destruction of the cabin.

Let's take a look at the different object with the fawn foundation at the upper part. If a concrete slab is removed at the bottom, then under it the pressure on the ground will be distributed more evenly, with a large surface of spiral, which cannot be said about the fire. The upper part of the booth, at this point, will sag more over time, as a result of which a crack will soon appear on the joint of the two blocks. Rational solutions here would be a combination of a fawn and stitch foundation with reinforced, horizontally reinforced walls in the area where the foundations are pressed.

The front butt of the indications for the baby is lower.

Another option for combining the foundations of connections with objects, which will be completed before the end of the day. Most often, their underground structures are divided into one type. In this case, there are three basic rules:

- on heaving soils it is not allowed to forcefully connect two buds;

- on non-heaving soils, the connection of different foundations and the walls of the booth with the bottom may be harsh;

- Concreting the sticks will only vibrate after the residual subsidence of the new building. For this purpose it is necessary to deprive him of “overwintering”.

Various schemes of combined foundations give designers a wide range of design possibilities. But don’t forget about the fact that the foundation of the building must be reliable and durable. Therefore, any engineering decisions need to be supported by developments.